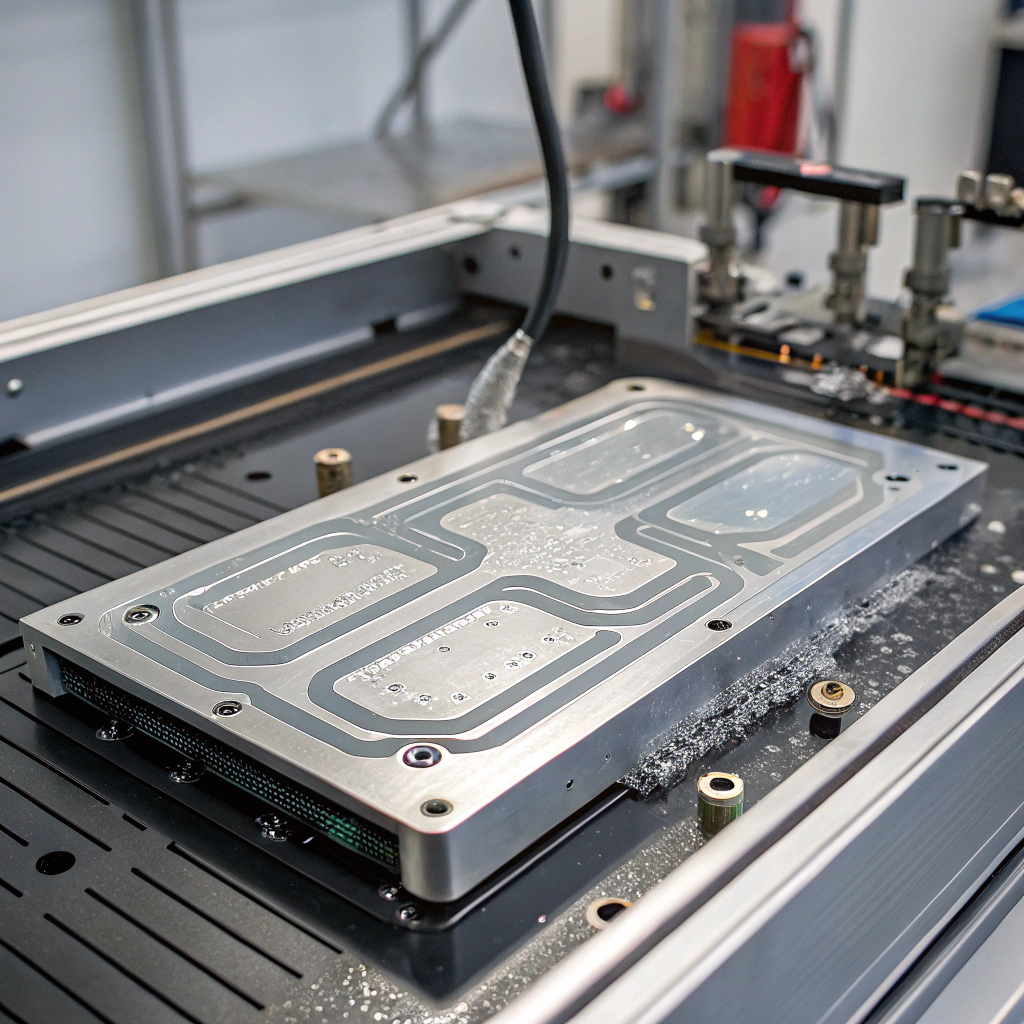

How to Calculate Pressure Drop in Liquid Cooling Plates?

Are you struggling with calculating the pressure drop in your liquid cooling plate? Understanding pressure loss can make or break your cooling system design.

Pressure drop in a liquid cooling plate is calculated using fluid dynamics principles, such as the Darcy-Weisbach equation. It is critical to account for system efficiency, heat dissipation, and fluid flow.

Understanding pressure drop isn’t just a matter of calculation; it’s about optimizing the performance of your cooling system. Let’s dive into the key aspects that affect pressure loss and how to compute it effectively.

What Defines Pressure Drop?

Pressure drop might seem like a small detail, but it directly impacts your cooling system’s efficiency and performance. What exactly defines pressure drop in liquid cooling plates?

Pressure drop is influenced by factors such as the flow rate, fluid properties, channel geometry, and the friction between the fluid and the surface of the cooling plate.

Pressure drop occurs when there is resistance to the flow of the cooling liquid through the channels of the plate. As the liquid moves, friction between the fluid and the surface of the plate causes a loss of pressure. This resistance is influenced by several factors.

Key Factors Defining Pressure Drop:

-

Flow Characteristics: The flow velocity and the fluid’s viscosity play a crucial role. Faster flow rates and fluids with low viscosity will experience less resistance and therefore, a lower pressure drop.

-

Channel Geometry: The design of the cooling channels is one of the most important aspects. Narrow channels or complex geometries, such as bends and twists, create more resistance, increasing the pressure drop. The shape of the channel and its length can dramatically affect the overall resistance.

-

Flow Regime: The Reynolds number helps determine the flow regime: whether the flow is laminar or turbulent. Laminar flow (low Reynolds number) typically results in lower pressure drops, whereas turbulent flow (high Reynolds number) increases pressure drop due to higher friction and chaotic fluid motion.

-

Surface Roughness: A smoother channel surface reduces friction, leading to less pressure drop. However, rougher surfaces create more drag on the fluid, raising the pressure required to maintain the same flow rate.

-

Viscosity and Density of the Fluid: These properties also significantly impact the pressure drop. High-density or highly viscous fluids tend to create higher resistance as they move through the system.

The pressure drop is directly tied to the efficiency of the cooling system. A higher pressure drop requires a more powerful pump to maintain the desired flow rate. Therefore, understanding the underlying causes of pressure drop can help you design a more efficient system, minimizing energy costs while maintaining adequate cooling performance.

Pressure drop is mainly influenced by channel geometry, flow velocity, and fluid properties.True

These factors all contribute to the friction and resistance in the system, leading to pressure loss.

Pressure drop is less affected by the Reynolds number and flow characteristics in turbulent flow.False

Turbulent flow increases pressure drop due to higher friction, and the Reynolds number is crucial in determining the flow regime.

Why Is Pressure Drop Critical to Performance?

Why should you care about pressure drop in your cooling system? How does it impact overall performance and energy efficiency?

Pressure drop is crucial because it determines the power required to pump the coolant through the system. Too high of a pressure drop can lead to inefficiency and inadequate cooling.

Pressure drop has a significant impact on the performance of a liquid cooling plate. In cooling systems, the primary objective is to dissipate heat effectively while minimizing energy consumption. High pressure drop requires more pump power, which increases operating costs. Additionally, if the pressure drop is too high, the flow rate of the cooling fluid decreases, which can result in poor heat dissipation and lower overall cooling efficiency.

Effects on System Efficiency:

-

Pump Power Requirements: A high pressure drop requires a more powerful pump to achieve the desired flow rate. This not only increases the power consumption but also adds wear and tear on the pump, leading to higher maintenance costs over time.

-

Heat Transfer Efficiency: As the flow rate decreases due to excessive pressure drop, the heat transfer capability of the system reduces. A slower flow means that the coolant spends more time in contact with the heated surface, potentially leading to less effective cooling.

-

Flow Instability: If the pressure drop is too high, it can lead to unstable flow conditions, especially in microchannels. This can cause localized boiling or other undesirable flow behaviors that further hinder the cooling performance.

-

Energy Consumption: Increased pressure drop leads to higher energy consumption because the pump must work harder to maintain the flow rate. If energy efficiency is a concern, it’s important to optimize the design to reduce unnecessary pressure losses.

Thus, understanding and controlling pressure drop is essential to designing a cooling system that operates efficiently, with optimal heat transfer and minimal energy consumption.

High pressure drop leads to reduced flow rate and increased energy consumption.True

When the pressure drop is high, the flow rate decreases, which requires more energy to maintain the same system performance.

Pressure drop does not affect pump power requirements in liquid cooling systems.False

The pressure drop directly impacts the power requirements of the pump, as more power is needed to overcome the resistance and maintain flow.

How to Compute and Simulate Flow Loss?

How can you compute pressure drop in your system? And how can simulations help you understand flow loss more accurately?

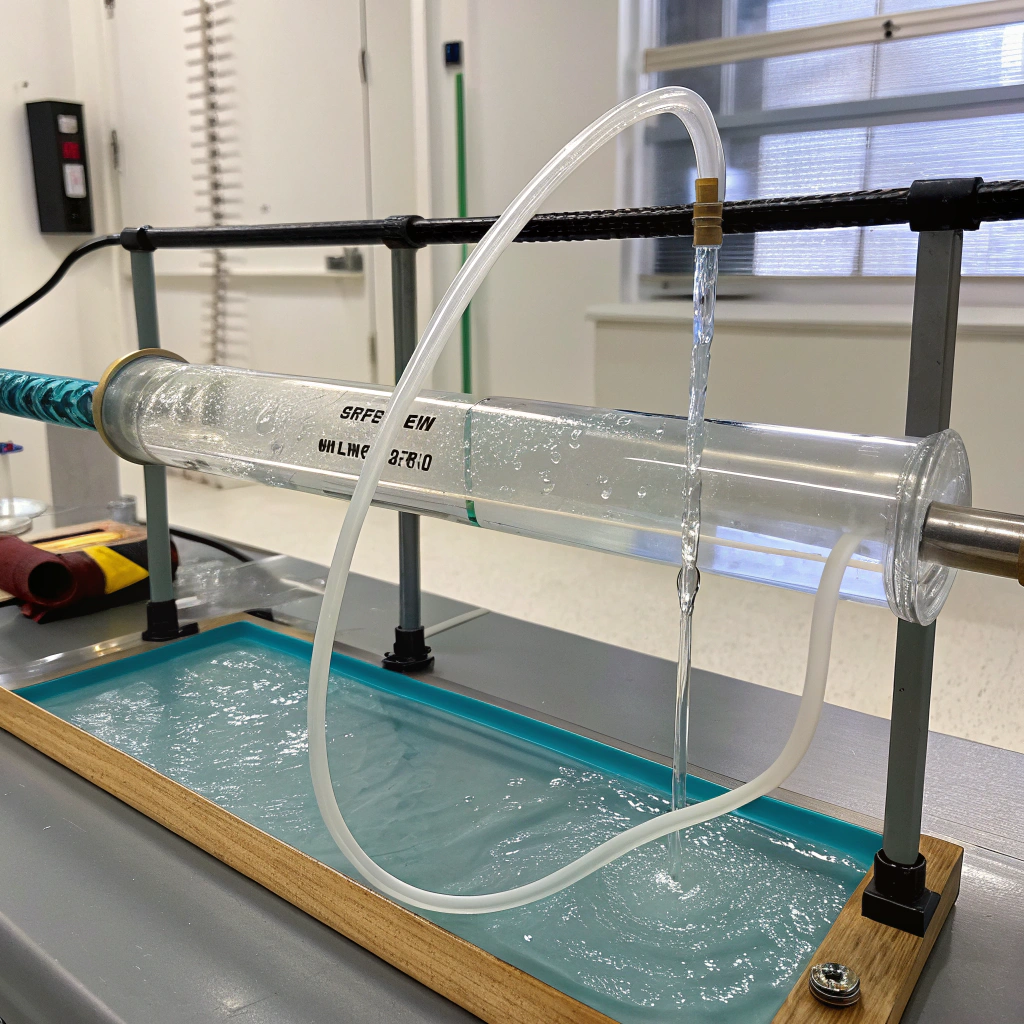

Flow loss, or pressure drop, can be computed using formulas like the Darcy-Weisbach equation, and simulated with CFD tools for more complex systems. These methods help ensure optimized system design.

Computing and simulating pressure drop involves both analytical and computational approaches. The Darcy-Weisbach equation is one of the most commonly used formulas to estimate pressure drop, as it accounts for the length of the flow path, the flow velocity, the fluid properties, and the pipe or channel characteristics.

However, for more complex systems or designs with intricate geometries, such as microchannels or cooling plates with bends, the Darcy-Weisbach equation may not be enough. In such cases, Computational Fluid Dynamics (CFD) simulations are invaluable. CFD tools model the fluid flow within the system, accounting for all factors that contribute to pressure drop, and provide detailed visualizations and calculations for every part of the cooling plate.

Analytical Approach:

For simple systems with regular pipe geometry, the Darcy-Weisbach equation can give a quick estimate of the pressure drop. Here’s how you would apply it:

[

\Delta P = f \cdot \frac{L}{D} \cdot \frac{\rho v^2}{2}

]

Where:

- ( \Delta P ) = Pressure drop (Pa)

- ( f ) = Friction factor (dimensionless)

- ( L ) = Length of the flow path (m)

- ( D ) = Diameter of the pipe or channel (m)

- ( \rho ) = Fluid density (kg/m³)

- ( v ) = Flow velocity (m/s)

This formula works well for estimating pressure drop in simple geometries. However, for more complicated designs, simulations become necessary.

Simulation Approach:

CFD tools like ANSYS Fluent or COMSOL Multiphysics offer advanced simulations, helping engineers visualize fluid flow and calculate pressure drop with greater accuracy. These tools take into account more complex factors such as microchannel design, surface roughness, and even transient flow behavior. By using CFD, you can simulate various flow scenarios, optimize the design, and predict performance before building the actual system.

The advantage of simulations is that they allow for more precise control and analysis of all parameters. For example, you can adjust flow rates, change channel dimensions, or even experiment with different fluids to find the most efficient solution without the need for physical prototypes.

CFD simulations provide a more accurate way to predict pressure drop in complex systems.True

CFD tools model fluid behavior more precisely and take into account intricate geometries that analytical methods can't capture.

Analytical methods like Darcy-Weisbach are always more accurate than CFD simulations.False

While Darcy-Weisbach is useful for simple systems, CFD simulations offer a higher degree of accuracy for complex geometries and flow conditions.

Conclusion

Understanding pressure drop in liquid cooling plates is crucial for designing an efficient system. By calculating pressure loss and using CFD simulations, you can optimize your cooling system for better performance and lower energy consumption.