How Does Aluminium Extrusion Work?

Aluminium extrusion is a fascinating process that transforms raw aluminum into custom shapes for various applications.

Aluminium extrusion involves heating aluminum billets, pressing them through a die to create specific profiles, and cooling them to solidify. This method is widely used in industries like construction, automotive, and electronics for its versatility and efficiency.

In this blog post, we will delve deeper into each step of the aluminium extrusion process, explore the materials used, and discuss the critical factors that can influence the quality and performance of the extruded profiles.

Aluminium extrusion is used in the automotive industry.True

The automotive industry utilizes aluminium extrusion for lightweight and durable components, enhancing vehicle performance and fuel efficiency.

Aluminium billets are cooled before being extruded.False

In the extrusion process, aluminium billets are heated before pressing, not cooled, to facilitate shaping through the die.

What Are the Key Advantages of Aluminium Extrusion?

Aluminium extrusion offers numerous advantages that make it an attractive choice for various industries. From lightweight strength to excellent corrosion resistance, let’s explore these benefits further.

The key advantages of aluminium extrusion include its lightweight yet strong properties, excellent corrosion resistance, versatility in shapes, cost-effectiveness in production, and eco-friendliness. These benefits make it ideal for a variety of applications.

Lightweight yet Strong

One of the primary advantages of aluminium extrusion is its lightweight nature coupled with remarkable strength. Aluminium is significantly lighter than steel, making it an ideal choice for industries like automotive and aerospace, where weight reduction is crucial.

| Property | Aluminium | Steel |

|---|---|---|

| Density | 2.7 g/cm³ | 7.85 g/cm³ |

| Strength-to-Weight Ratio | High | Moderate |

This high strength-to-weight ratio allows for more efficient designs and structures, leading to reduced energy consumption and improved performance in applications ranging from automotive parts to building materials.

Excellent Corrosion Resistance

Aluminium has an inherent ability to resist corrosion due to its protective oxide layer. This characteristic makes aluminium extrusion a perfect choice for outdoor applications such as architecture and outdoor equipment.

- Durability: Aluminium extrusions can withstand harsh weather conditions without significant degradation, enhancing the lifespan of products made from it.

- Maintenance: Minimal maintenance is required compared to other materials, reducing long-term costs.

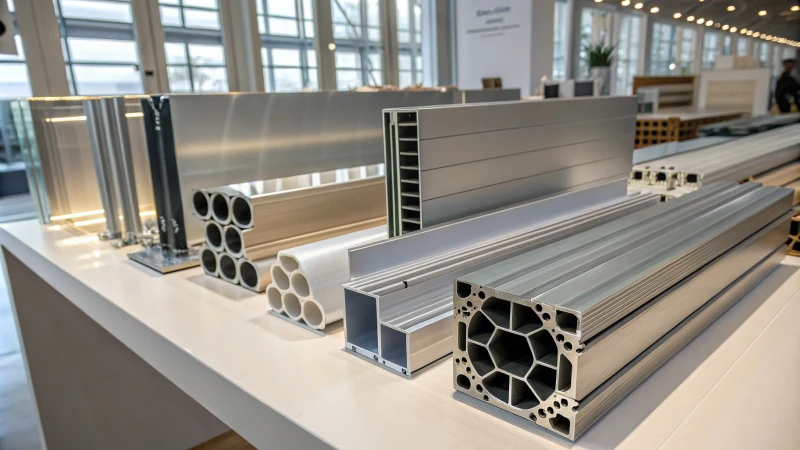

Versatile and Customizable Shapes

Another key advantage of aluminium extrusion is the ability to create custom shapes. The extrusion process allows manufacturers to design profiles tailored to specific needs, accommodating a wide range of applications:

- Complex Profiles: Unique and intricate designs can be easily achieved, which is particularly valuable in the architectural and artistic fields.

- Endless Design Possibilities: Manufacturers can produce bespoke profiles that meet precise specifications, improving overall product functionality.

Explore more on custom designs.

Cost-Effectiveness in Production

When considering mass production, aluminium extrusion offers significant cost advantages:

- Reduced Waste: The extrusion process minimizes waste by producing the final shape directly from the raw material.

- Efficiency: High-speed production capabilities lead to faster turnaround times, making it more economical for large-scale projects.

- Recyclability: Aluminium is fully recyclable without losing its properties, contributing to sustainability and cost savings in material procurement.

This combination of factors results in lower overall project costs, especially for companies like David’s outdoor equipment business.

Eco-Friendly Material Choice

As sustainability becomes increasingly important, aluminium extrusion stands out as an environmentally friendly option:

- Sustainable Sourcing: Aluminium can be sourced locally, reducing transportation emissions and supporting local economies.

- Energy Efficiency: The manufacturing process can be optimized for energy efficiency, further lowering the environmental footprint.

With its recyclability and lower energy usage, aluminium extrusion aligns well with sustainable practices in various industries. For more insights on sustainable practices, check out this resource.

Aluminium is lighter than steel, enhancing performance.True

Aluminium's lower density (2.7 g/cm³) compared to steel (7.85 g/cm³) improves efficiency in automotive and aerospace applications.

Aluminium extrusion requires high maintenance over time.False

Contrary to this claim, aluminium's corrosion resistance minimizes maintenance needs, making it cost-effective for long-term use.

How Do Different Aluminium Alloys Affect the Extrusion Process?

Understanding how aluminium alloys influence the extrusion process is crucial for achieving desired material properties and application suitability.

Different aluminium alloys affect the extrusion process by influencing temperature sensitivity, malleability, and mechanical properties, which determine their suitability for various applications.

Understanding Aluminium Alloys in Extrusion

Aluminium alloys are categorized into two main types: wrought and cast. Each type offers different properties that significantly influence the extrusion process.

Wrought Alloys: These alloys are worked into shape through mechanical processes. They are further divided into several series based on their primary alloying elements:

| Alloy Series | Main Alloying Element | Properties |

|---|---|---|

| 1xxx | Pure Aluminium | Excellent corrosion resistance, high ductility. |

| 2xxx | Copper | High strength, moderate corrosion resistance. |

| 3xxx | Manganese | Good workability, moderate strength. |

| 6xxx | Magnesium & Silicon | Good corrosion resistance, medium strength. |

Understanding these properties allows manufacturers to select the right alloy for specific applications. For instance, lightweight alloys are essential in automotive manufacturing to improve fuel efficiency while maintaining strength.

Impact on the Extrusion Process

Different aluminium alloys affect the extrusion process in various ways:

-

Temperature Sensitivity: Alloys respond differently to heat. For example, 6061 alloys require precise temperature control to prevent cracking during extrusion, whereas 7075 alloys can withstand higher temperatures but may be more challenging to extrude due to their strength.

- Example: The typical extrusion temperature for 6061 is around 400-500°C.

- Tip: Adjust heating strategies based on alloy choice to optimize results.

-

Malleability: Some alloys offer better malleability than others, which is critical during the extrusion phase. Malleable alloys can be formed into complex shapes without cracking, while less malleable options may lead to defects.

- Recommendation: Use 3003 alloy for intricate designs where flexibility is crucial.

-

Mechanical Properties: The final strength and durability of the extruded product are influenced by the alloy used. Stronger alloys can withstand greater loads, making them suitable for structural applications like beams in construction.

- Comparison: A table illustrating tensile strengths of common alloys can help visualize this:

| Alloy | Yield Strength (MPa) | Ultimate Strength (MPa) |

|---|---|---|

| 6061 | 240 | 310 |

| 7075 | 570 | 700 |

| 2024 | 480 | 550 |

This knowledge is critical for selecting materials that meet strength requirements in applications ranging from aerospace to construction.

Application Suitability

The choice of aluminium alloy not only affects the extrusion process but also its suitability for specific applications. For instance:

- Aerospace Components: Require high-strength alloys like 7075 due to weight restrictions and structural integrity demands.

- Building Facades: Often utilize 6063 due to its excellent finish and extrudability.

- Automotive Parts: Demand a balance of strength and weight, often achieved with 6000-series alloys like 6061.

To ensure optimal performance in your projects, consider consulting industry standards for recommended alloys based on application needs.

Wrought alloys are more malleable than cast alloys.True

Wrought alloys undergo mechanical processing, enhancing their malleability compared to cast alloys, which are less flexible during shaping.

7075 aluminium alloy is ideal for lightweight automotive parts.False

7075 alloy is known for its high strength, making it suitable for structural applications rather than lightweight automotive parts.

What Industries Benefit Most from Aluminium Extrusion?

Aluminium extrusion is a versatile manufacturing process that significantly benefits multiple industries. Discover which sectors harness its advantages most effectively.

Industries that benefit from aluminium extrusion include automotive, construction, aerospace, and renewable energy. Its lightweight and durable characteristics make it essential for components across these sectors.

Automotive Industry

Aluminium extrusion plays a vital role in the automotive sector due to its lightweight and strength properties. Extruded aluminium is extensively used for components like chassis, heat exchangers, and various body parts.

This not only helps in reducing the overall weight of vehicles, thus improving fuel efficiency, but also enhances safety due to the material’s high strength-to-weight ratio.

Examples of applications include:

| Component | Benefits |

|---|---|

| Chassis | Reduces weight and increases strength |

| Heat Exchangers | Improved thermal management |

| Body Panels | Lightweight, better aesthetics |

The shift towards electric vehicles has further increased demand for aluminium extrusion, as manufacturers seek to reduce weight and improve performance.

For more information on this topic, check out our guide on automotive applications of aluminium.

Construction Sector

The construction industry is another major beneficiary of aluminium extrusion. Its versatility allows for a range of applications, including window frames, doors, and roofing systems.

Aluminium extrusions can be designed to meet specific architectural needs, providing both functional and aesthetic advantages.

Some notable uses include:

| Application | Features |

|---|---|

| Window Frames | Lightweight, energy-efficient |

| Roof Structures | Durable, corrosion-resistant |

| Decorative Panels | Customizable designs available |

These attributes make aluminium a preferred choice for sustainable building practices.

To learn more about its impact on construction, explore our article on sustainable building materials.

Aerospace Industry

In aerospace, weight reduction is crucial for enhancing fuel efficiency and performance. Aluminium extrusion provides an ideal solution with its ability to create lightweight yet robust components such as fuselage frames and wing structures.

The aerospace sector benefits from:

| Component | Advantages |

|---|---|

| Fuselage Frames | Enhanced structural integrity |

| Wing Structures | Lightweight, increased fuel efficiency |

Aluminium extrusions are also used in aircraft interiors, contributing to overall design and passenger comfort.

For further insights into aerospace applications, read our detailed post on aluminium in aerospace engineering.

Renewable Energy

The renewable energy sector has increasingly adopted aluminium extrusion in solar panel frames and wind turbine components. The material’s durability and resistance to environmental factors make it a favorable choice for these applications.

Key benefits include:

| Application | Key Features |

|---|---|

| Solar Panel Frames | Lightweight, corrosion-resistant |

| Wind Turbine Blades | High strength-to-weight ratio |

These features support the efficiency and longevity of renewable energy systems.

To delve deeper into this area, check our exploration of aluminium’s role in renewable energy.

Aluminium extrusion reduces vehicle weight in the automotive industry.True

Reducing vehicle weight enhances fuel efficiency and safety, making aluminium extrusion crucial for automotive components.

Aluminium is rarely used in construction applications today.False

This claim is false; aluminium extrusion is widely used for window frames, roofing, and more in modern construction.

What Common Challenges Are Faced During Aluminium Extrusion?

Aluminium extrusion presents various challenges that manufacturers must navigate to ensure high-quality products. Understanding these common obstacles can help improve production efficiency and reduce costs.

Common challenges faced during aluminium extrusion include material selection issues, temperature control problems, die design complications, cooling rate management, quality control difficulties, and logistical hurdles.

Understanding Common Challenges in Aluminium Extrusion

Aluminium extrusion is a complex manufacturing process that involves several stages. Each stage presents unique challenges that can impact the overall quality and efficiency of the production. Let’s explore some common challenges faced during this process:

1. Material Selection Issues

Selecting the right aluminium alloy is crucial for achieving desired mechanical properties. Different alloys have varying levels of strength, corrosion resistance, and flexibility. Choosing an inappropriate alloy can lead to:

- Weak Profiles: Reduced structural integrity.

- Poor Surface Finish: Increased costs due to rework.

2. Temperature Control

Maintaining optimal heating temperatures for the aluminium billets is essential. Incorrect temperature management can result in:

- Cracking or Deformation: If the material is overheated, it may become brittle, leading to cracking during extrusion.

- Inconsistent Quality: Variations in temperature can produce profiles with uneven mechanical properties.

| Problem | Consequences | Solutions |

|---|---|---|

| Cracking | Weak structural integrity | Precise temperature control |

| Poor surface finish | Increased rework costs | Regular calibration of heating systems |

3. Die Design Challenges

The extrusion die plays a critical role in shaping the aluminium. Issues with die design can cause:

- Poor Profile Accuracy: Deviations from specifications that affect usability.

- Increased Wear and Tear: Leads to higher maintenance costs and downtime.

4. Cooling Rate Management

After extrusion, the cooling process must be controlled to avoid:

- Internal Stresses: Rapid cooling can induce stress, leading to warping or cracking.

- Inconsistent Hardening: Variability in cooling rates can produce profiles with inconsistent mechanical properties.

5. Quality Control Complications

Quality assurance is vital in aluminium extrusion to meet industry standards. Common QC challenges include:

- Dimensional Non-Conformance: Profiles that do not meet specified dimensions require rework or scrapping.

- Surface Defects: Issues such as oxidation or scratches can affect product quality and appearance.

To mitigate these issues, a robust quality control system should be implemented that includes:

- Regular Inspections: Conduct dimensional checks and strength testing at various stages.

- Standardized Procedures: Utilize international standards like ASTM or ISO for testing and certification.

6. Logistical Challenges

Finally, logistics can pose significant challenges in the extrusion process, particularly regarding:

- Timely Delivery: Delays in material sourcing or product shipment can disrupt production schedules.

- Storage Requirements: Ensuring proper storage conditions to prevent damage during transit and before installation.

Addressing these logistical hurdles involves strategic planning and reliable supplier partnerships.

For more insights on improving your aluminium extrusion processes, check out these resources:

- Explore best practices

- Learn about material selection

By understanding these challenges, manufacturers can develop strategies to enhance efficiency, quality, and customer satisfaction in their aluminium extrusion operations.

Material selection directly impacts extrusion quality.True

Choosing the right aluminium alloy is essential for achieving desired mechanical properties and preventing weak profiles.

Poor temperature control can lead to cracking in extrusions.True

Incorrect heating temperatures may cause brittleness, resulting in cracks during the aluminium extrusion process.

How Can Quality Control Impact the Final Product in Aluminium Extrusion?

Understanding how quality control impacts aluminium extrusion can help manufacturers enhance product reliability and customer satisfaction.

Quality control in aluminium extrusion is vital as it ensures dimensional accuracy, surface finish, and mechanical properties, directly influencing the final product’s performance and market acceptance.

Importance of Quality Control in Aluminium Extrusion

Quality control (QC) is essential in aluminium extrusion as it directly influences the integrity and performance of the final product. Effective QC measures ensure that every aspect of the extrusion process meets specific standards, from material selection to post-production inspection. This not only enhances product reliability but also boosts customer satisfaction.

Consider the following areas where quality control makes a significant impact:

-

Dimensional Accuracy: QC processes involve precise measurements during production. For instance, if the profile’s dimensions deviate even slightly from specifications, it may lead to fitting issues during installation.

-

Surface Finish: The aesthetic quality of the extruded profiles is critical, especially in consumer-facing applications. QC checks for surface imperfections, ensuring that products are visually appealing and ready for the market.

-

Mechanical Properties: Quality control verifies that the aluminium alloys used provide the necessary strength and flexibility for intended applications. For example, automotive parts need to withstand rigorous conditions; hence, thorough testing is crucial.

Types of Quality Control Measures

Implementing various QC measures can significantly enhance the extrusion process. Here’s a breakdown of common practices:

| QC Measure | Description | Impact on Product |

|---|---|---|

| Material Inspection | Analyzing raw materials for composition and properties before use. | Ensures consistency and reliability. |

| Process Monitoring | Continuous observation of extrusion parameters (temperature, pressure). | Maintains product integrity. |

| Dimensional Checks | Regularly measuring profiles against specifications during production. | Prevents installation issues. |

| Destructive Testing | Performing tests that can cause failure (e.g., tensile testing) to assess material strength. | Guarantees durability and safety. |

| Final Inspection | Comprehensive checks on finished products for defects and adherence to standards. | Ensures market readiness. |

Consequences of Poor Quality Control

Neglecting quality control can lead to severe ramifications, including:

- Increased Defects: Higher defect rates result in wasted materials and time, directly impacting profitability.

- Customer Dissatisfaction: Products that fail to meet standards can harm a company’s reputation and lead to loss of customers.

- Compliance Issues: Failing to adhere to industry standards can result in legal repercussions and financial penalties.

For instance, if an extruded aluminium profile fails a strength test, it may not only result in recalls but also damage trust in the brand.

Best Practices for Quality Control in Aluminium Extrusion

To effectively manage quality control, companies should adopt best practices such as:

- Standard Operating Procedures (SOPs): Establish clear guidelines for each stage of the extrusion process to maintain consistency.

- Training Programs: Regular training for employees on QC measures and their importance ensures everyone is aligned with quality goals.

- Feedback Loops: Implement systems to gather feedback from production to continuously improve processes based on real-time data.

- Regular Audits: Conduct frequent internal audits to identify areas for improvement and reinforce accountability across teams.

- Use of Technology: Incorporate automation and advanced monitoring systems to enhance precision in quality checks.

For more insights on implementing effective quality control measures in aluminium extrusion, check out best practices or quality standards.

Quality control ensures dimensional accuracy in aluminium extrusion.True

Dimensional checks during production prevent fitting issues, ensuring products meet specifications and function correctly in their applications.

Poor quality control leads to increased customer satisfaction.False

Neglecting quality control results in defects, harming product reliability and ultimately reducing customer satisfaction and trust in the brand.

Conclusion

Aluminium extrusion transforms raw aluminium into custom shapes through heating and pressing, offering benefits like lightweight strength and versatility for industries such as automotive and construction.