What is V-Slot Aluminum?

Discover the innovative world of V-Slot aluminum!

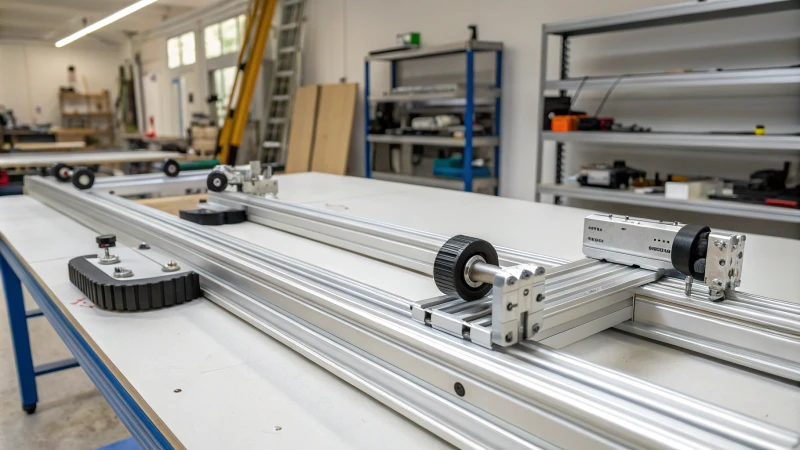

V-Slot aluminum is a specialized type of aluminum extrusion featuring a V-shaped groove that facilitates smooth linear movement when paired with V-wheels. Its modular design and versatility make it ideal for various applications, including CNC machines, 3D printers, and automation systems.

Continue reading to explore the unique benefits of V-Slot aluminum and how it can transform your projects with its exceptional properties and applications.

What Makes V-Slot Aluminum Ideal for Linear Motion Systems?

Discover why V-Slot aluminum is a top choice for linear motion systems, thanks to its unique design features and practical advantages that ensure smooth, reliable movement.

V-Slot aluminum is ideal for linear motion systems due to its precision V-shaped groove, modular design for easy assembly, lightweight yet strong structure, and corrosion resistance, making it versatile across various applications.

Precision Engineering at Its Best

V-Slot aluminum’s V-shaped groove is not just a design element; it’s engineered for precision. This unique feature ensures that the V-wheels glide effortlessly along the profile, maintaining a linear path crucial for applications like CNC machines and 3D printers.

The precise alignment provided by the V-groove minimizes friction, which can enhance the lifespan of moving parts. For example, in a CNC machine, precision is paramount, as even the slightest misalignment can lead to errors in machining.

Modular Flexibility

One of the standout characteristics of V-Slot aluminum is its modular design. This allows users to configure and reconfigure setups without extensive machining or custom fabrication. Whether you need a simple frame or a complex motion system, V-Slot can adapt to your requirements.

| Feature | Benefit |

|---|---|

| Modular Design | Easy customization |

| Lightweight | Simple handling |

| Corrosion Resistant | Durability in diverse environments |

This adaptability makes it ideal for DIY enthusiasts and professionals alike who require quick adjustments to their projects.

Lightweight Yet Strong

Another reason why V-Slot aluminum is preferred in linear motion systems is its strength-to-weight ratio. Made from aluminum alloy, it strikes an excellent balance between being lightweight and robust, which is particularly beneficial in applications where weight reduction is critical, such as in robotics or portable CNC machines.

Corrosion Resistance for Longevity

Aluminum’s inherent corrosion resistance further enhances the suitability of V-Slot aluminum for various environments, including outdoor applications. This quality ensures that the profiles remain functional over time, regardless of exposure to moisture or humidity.

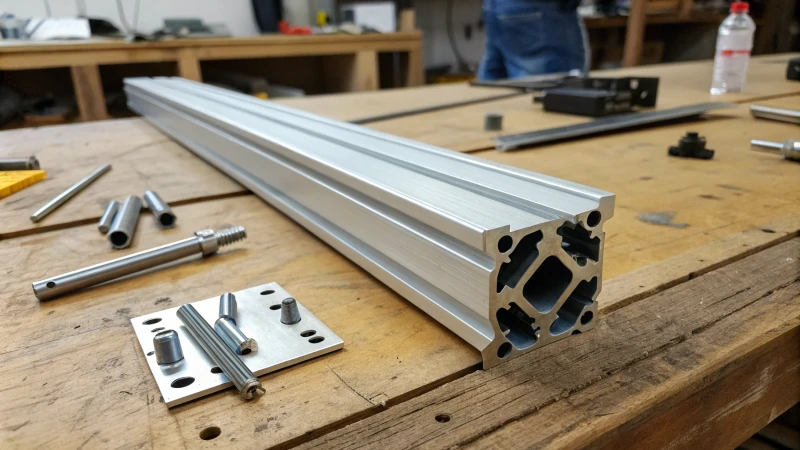

Ease of Assembly

V-Slot aluminum is designed for user-friendliness. It typically utilizes standard fasteners like T-nuts and bolts for assembly. This ease of assembly is not only time-saving but also cost-effective, making it accessible for businesses and hobbyists looking to create their own linear motion systems without specialized tools.

For those considering building automation systems or custom machines, the ability to easily integrate components like motors and brackets is invaluable.

Applications Across Industries

The versatility of V-Slot aluminum shines through in its broad range of applications. From 3D printers to automation systems, its benefits are realized across many sectors:

- CNC Machines: Supports precise linear movements essential for accurate machining.

- 3D Printers: Ensures smooth operation for the print head and bed.

- Robotics: Facilitates fluid motion in robotic arms and conveyor systems.

Exploring more about these applications can provide insights into how V-Slot aluminum might benefit your specific projects. Check out applications of V-Slot for further exploration!

How Does V-Slot Aluminum Compare to T-Slot Aluminum?

Curious about the differences between V-Slot and T-Slot aluminum? Both have unique advantages, but understanding their specific applications can help you choose the right one for your project.

V-Slot aluminum features a V-shaped groove ideal for linear motion systems, while T-Slot aluminum offers a versatile T-shaped slot suitable for structural frames. Choosing between them depends on your project’s needs.

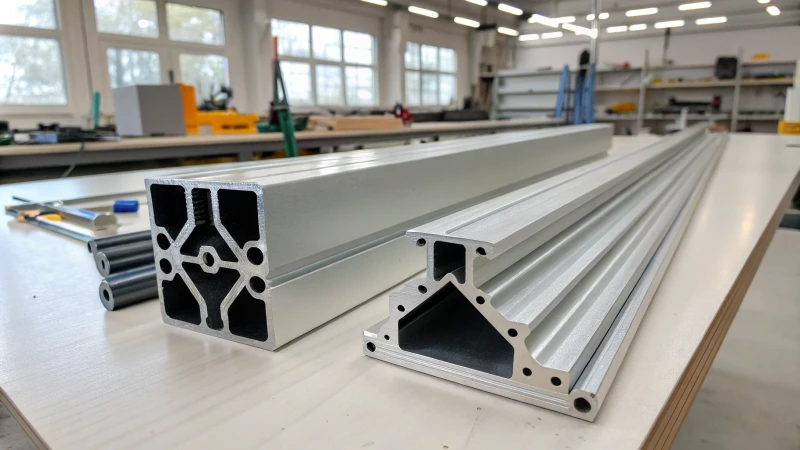

Understanding V-Slot and T-Slot Aluminum

Both V-Slot and T-Slot aluminum are popular extrusion profiles used in various applications, but they have distinct characteristics that make them suited for different purposes. V-Slot is primarily designed for linear motion systems, while T-Slot offers versatility in structural framing.

Key Differences in Design

The main distinction between V-Slot and T-Slot lies in their profiles:

| Feature | V-Slot Aluminum | T-Slot Aluminum |

|---|---|---|

| Groove Shape | V-shaped groove for linear motion | T-shaped slots for versatile connections |

| Usage | Ideal for linear motion applications | Suitable for structural frames and assemblies |

| Component Pairing | Requires V-wheels or similar components | Compatible with a wide range of connectors |

| Stability | Provides smooth guidance and stability | Offers flexibility in joining multiple profiles |

This table illustrates how the designs cater to different functionalities, showcasing their unique advantages.

Applications

V-Slot is commonly used in:

- CNC Machines: Where precise linear motion is essential for cutting processes.

- 3D Printers: Facilitating smooth movement of print heads or platforms.

- Robotics: Supporting linear movement in robotic arms and other applications.

On the other hand, T-Slot is more versatile, being used in:

- Workstations: Allowing for customizable setups that can be easily reconfigured.

- Shelving Units: Providing a robust structure for storing equipment or materials.

- Automated Systems: Enabling the construction of frames that support various machinery.

Cost Considerations

When evaluating the cost-effectiveness of these materials, it’s important to consider not just the price per meter but also the overall value they provide. V-Slot may be more suitable for projects requiring precise linear movement, while T-Slot can often be more economical for large-scale structural applications due to its flexibility and ease of assembly.

For further insights on budgeting for these materials, you can check out cost analysis strategies.

Assembly and Customization

In terms of assembly, both V-Slot and T-Slot aluminum are user-friendly. However, their methods of connection differ:

- V-Slot: Typically requires specific fasteners and components like V-wheels and brackets.

- T-Slot: Utilizes standard fasteners such as bolts and nuts, allowing greater ease in adding or removing components.

This makes T-Slot often preferred for projects where flexibility and modularity are paramount. If you’re interested in learning more about assembly techniques, visit assembly tips.

Conclusion (Note: omit this section in your final draft)

While it’s tempting to conclude here, the nuances between V-Slot and T-Slot aluminum profiles warrant further exploration. Each serves its purpose in various applications, providing unique benefits that cater to specific project requirements.

What Are the Key Benefits of Using V-Slot Aluminum in DIY Projects?

Are you considering using V-Slot aluminum for your next DIY project? Discover the key benefits that make this material a top choice for builders and innovators alike.

V-Slot aluminum offers numerous benefits for DIY projects, including modularity, lightweight strength, ease of assembly, precision in movement, and cost-effectiveness, making it ideal for custom builds like CNC machines and 3D printers.

Modular Design for Customization

V-Slot aluminum is celebrated for its modular design, which allows for incredible customization in DIY projects. Users can easily cut, connect, and reconfigure the profiles to suit specific needs.

For instance, a hobbyist can create a custom CNC machine frame using different lengths and angles of V-Slot. This flexibility enables unique designs that can adapt as project requirements evolve. Learn more about modular construction to maximize your project’s potential.

Strength Meets Lightweight

Made from aluminum alloy, V-Slot aluminum offers an excellent strength-to-weight ratio. This makes it ideal for projects that require both durability and ease of transport.

| Feature | Benefits |

|---|---|

| Strength | High load-bearing capacity |

| Lightweight | Easy handling and assembly |

| Corrosion-resistant | Long-lasting in various environments |

This balance of properties means that DIY builders can construct complex systems without worrying about excessive weight or structural failure. Find out more about strength-to-weight ratios in materials for projects.

Easy Assembly Process

One of the standout benefits of V-Slot aluminum is its straightforward assembly process. It utilizes standard fasteners like T-nuts and bolts, which simplifies the attachment of components.

This feature reduces the need for specialized tools or skills, making it accessible for beginners while still appealing to experienced builders. For those interested in learning more about DIY assembly techniques, this is a perfect starting point.

Precision and Stability in Motion

The V-shaped groove is not just a defining characteristic; it enhances precision in movement. When paired with V-wheels, these profiles facilitate smooth linear motion essential in applications like 3D printers and robotic arms.

The design ensures that moving parts remain stable and aligned, crucial for projects demanding high accuracy. Explore the importance of precision in DIY builds to ensure your projects meet professional standards.

Cost-Effectiveness for DIY Enthusiasts

V-Slot aluminum is a cost-effective alternative compared to traditional materials like steel or custom-manufactured components. Its modular nature allows for fewer wasted materials and simpler builds, ultimately saving costs.

By selecting V-Slot for your projects, you not only reduce expenses but also enhance the overall quality of your builds due to its durability and performance. Delve deeper into cost-effective materials to elevate your project budget management.

Which Industries Can Benefit from V-Slot Aluminum Applications?

V-Slot aluminum applications extend far beyond simple structures. Discover how diverse industries leverage this versatile material for efficiency and innovation.

V-Slot aluminum profiles benefit industries such as manufacturing, robotics, 3D printing, construction, and automotive by providing customizable solutions for precision movement and structural integrity.

1. Manufacturing Industry

The manufacturing sector is a primary benefactor of V-Slot aluminum applications. With its ability to create CNC machines and routers, manufacturers can achieve precise machining and cutting. This capability is crucial for producing high-quality components with minimal waste.

In addition to CNC machines, automation systems utilizing V-Slot profiles enhance production efficiency by facilitating the movement of materials along assembly lines.

2. Robotics

Robotics is another field where V-Slot aluminum shines. It allows engineers to build robust robotic arms and motion control systems that require smooth linear movement. The versatility of V-Slot enables designers to create custom solutions tailored to specific tasks, enhancing overall productivity.

For example, robotic automation in warehouses often leverages V-Slot profiles for constructing movable shelving and sorting systems that increase operational efficiency.

3. 3D Printing

The rise of 3D printing has seen an increased application of V-Slot aluminum profiles, especially in DIY projects. Many enthusiasts opt for V-Slot due to its ease of assembly and customization options. This modularity allows users to design and build their own 3D printers, maximizing their creativity while ensuring precise movements of the print head and bed.

A significant number of popular 3D printer designs incorporate V-Slot for its strength and reliability, making it an ideal choice for hobbyists and professionals alike.

4. Construction and DIY Projects

V-Slot aluminum’s adaptability makes it highly suitable for various construction applications. It’s widely used for building custom frames, workstations, and even lightweight structural components in construction projects.

With its ability to be cut and configured easily, DIY enthusiasts often utilize V-Slot to create bespoke solutions that cater to their specific needs, such as home improvement projects or custom furniture designs.

5. Automotive Industry

The automotive industry benefits from V-Slot aluminum in several ways, particularly in manufacturing fixtures and equipment used for assembly lines. The lightweight nature of aluminum helps in reducing the overall weight of vehicles, contributing to better fuel efficiency.

Moreover, V-Slot is used for creating custom tooling that aids in the production of vehicle parts, allowing manufacturers to streamline their processes without sacrificing quality or performance.

Summary Table of Industries Benefiting from V-Slot Aluminum

| Industry | Applications | Benefits |

|---|---|---|

| Manufacturing | CNC machines, routers | Precision machining |

| Robotics | Robotic arms, automation systems | Customization and efficiency |

| 3D Printing | DIY printers, custom frames | Ease of assembly |

| Construction | Frames, workstations | Modularity |

| Automotive | Manufacturing fixtures | Weight reduction |

V-Slot aluminum profiles are versatile tools that cater to various industries by providing solutions that enhance productivity, precision, and customization. Their ability to adapt to different applications makes them a valuable resource across sectors.

What Should You Consider When Purchasing V-Slot Aluminum?

When considering the purchase of V-Slot aluminum, several crucial factors come into play to ensure you make an informed decision.

Purchasing V-Slot aluminum requires careful consideration of load capacity, material specifications, dimensions, compatibility with other components, supplier reliability, and environmental factors to ensure quality and suitability for your project.

Understanding Your Project Requirements

Before purchasing V-Slot aluminum, it’s essential to clearly define your project requirements. Consider the following aspects:

- Load Capacity: Determine how much weight the V-Slot needs to support. This will influence the profile size and material thickness you should select.

- Precision Needs: If your project demands high precision, ensure that the V-groove design aligns with your linear motion needs. The V-wheel specifications should also be compatible.

Material Specifications

V-Slot aluminum profiles come in various material grades. It’s crucial to know:

- Alloy Type: Common alloys include 6061 and 6063. For strength and durability, 6061 is recommended.

- Surface Treatment: Anodized finishes improve corrosion resistance. Verify the treatment options with suppliers for specific environments.

| Alloy Type | Strength | Corrosion Resistance | Common Uses |

|---|---|---|---|

| 6061 | High | Good | Structural frames, automotive |

| 6063 | Medium | Excellent | Architectural applications, furniture |

Dimensions and Profiles

Understanding the dimensions of V-Slot profiles is key. Consider:

- Profile Size: They come in various widths and heights. Select a size that fits your design needs.

- Length: V-Slot can be cut to desired lengths. Check if the supplier offers custom cutting services.

Assembly and Compatibility

For ease of assembly, verify:

- Fasteners: Ensure you have the right T-nuts and bolts compatible with your V-Slot profile. Standard sizes facilitate easier assembly.

- Compatible Components: If integrating with other systems (e.g., motors, brackets), check compatibility with standard components. You can look for standard components that work seamlessly.

Cost and Supplier Reliability

Finally, evaluate cost and supplier reliability:

- Cost vs Quality: While cheaper options may seem attractive, they might compromise quality. Always prioritize durability for outdoor projects.

- Supplier Reviews: Research suppliers for customer feedback. A reliable supplier will understand your needs and provide consistent quality.

Environmental Considerations

As a conscious buyer, consider:

- Sustainability: Look for suppliers who prioritize sustainable sourcing of materials. This not only benefits the environment but also enhances your brand image in the market.

- Recyclability: Aluminum is recyclable; ensure that your supplier follows eco-friendly practices in their manufacturing processes.

By taking these factors into account, you can ensure a successful purchase of V-Slot aluminum that meets your project’s specific requirements.

Conclusion

V-Slot aluminum is a specialized extrusion with a V-shaped groove designed for linear motion systems, offering versatility and ease of assembly in various applications.