Anodized aluminium profiles in electronics product

Discover the transformative power of anodized aluminum in electronics!

Anodized aluminum profiles enhance electronic products by providing superior durability, corrosion resistance, and aesthetic appeal. This process not only improves the longevity of components but also ensures that devices maintain their sleek appearance over time.

In the following sections, we will explore the various advantages of anodized aluminum, its applications in electronics, and how it compares to other materials. Whether you’re a manufacturer or a design enthusiast, the insights shared here will be invaluable.

What are the key benefits of anodized aluminum in electronic applications?

Anodized aluminum offers numerous advantages for electronic applications. Understanding these benefits can significantly impact product design and durability.

The key benefits of anodized aluminum in electronic applications include enhanced durability, improved thermal management, effective EMI shielding, and attractive aesthetics, making it an ideal choice for various electronic components.

Enhanced Durability and Resistance to Wear

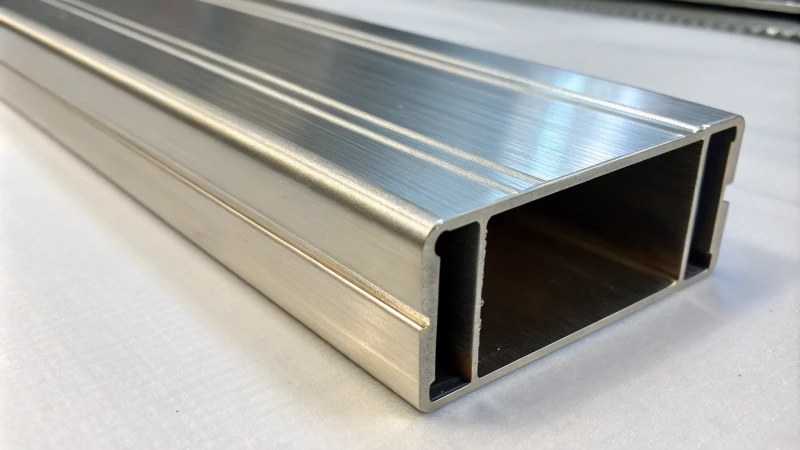

Anodized aluminum is known for its exceptional durability. The anodization process creates a thick, protective oxide layer on the aluminum surface. This layer significantly enhances resistance to scratches, abrasions, and corrosion.

The table below highlights how anodized aluminum compares to untreated aluminum in terms of durability:

| Property | Untreated Aluminum | Anodized Aluminum |

|---|---|---|

| Scratch Resistance | Low | High |

| Corrosion Resistance | Moderate | Excellent |

| Impact Resistance | Moderate | High |

In electronic applications, this durability ensures that devices maintain their appearance and functionality over time. Explore more about anodization.

Improved Thermal Management

Another key benefit of anodized aluminum in electronics is its thermal management capabilities. Due to its excellent thermal conductivity, anodized aluminum helps dissipate heat efficiently from sensitive electronic components. This feature is crucial for maintaining optimal operating temperatures and extending the lifespan of devices.

For instance, in applications like heat sinks or casings for power electronics, anodized aluminum provides an effective solution by facilitating heat transfer away from critical components. Learn about thermal properties.

Electromagnetic Interference (EMI) Shielding

Anodized aluminum surfaces also offer protection against electromagnetic interference (EMI). This is particularly beneficial in the design of electronic devices where stability and performance are critical. The anodized layer acts as a barrier, reducing the likelihood of interference that could disrupt device functionality.

A comparison of EMI shielding effectiveness is illustrated below:

| Material Type | EMI Shielding Effectiveness |

|---|---|

| Bare Aluminum | Low |

| Anodized Aluminum | Moderate to High |

This property makes anodized aluminum an ideal choice for sensitive electronic applications, ensuring reliable performance in environments susceptible to EMI. Discover more about EMI shielding.

Aesthetic Appeal with Functional Benefits

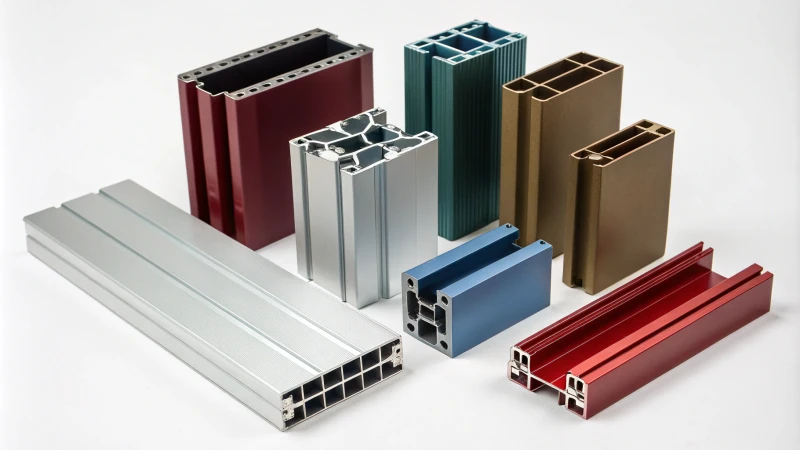

In addition to its functional benefits, anodized aluminum offers aesthetic appeal. The anodization process allows for various colors and finishes that enhance the visual aspect of consumer electronics. This combination of aesthetics and functionality is particularly attractive in markets like consumer electronics, where design plays a crucial role in product success.

A brief overview of aesthetic options:

| Finish Type | Description |

|---|---|

| Matte | Non-reflective finish |

| Glossy | High shine finish |

| Colored Anodized | Customizable colors |

This ability to customize the appearance without sacrificing performance makes anodized aluminum a preferred material in the industry. See more examples of anodized finishes.

How does anodizing improve corrosion resistance in aluminum profiles?

Anodizing transforms aluminum into a highly durable material that resists corrosion. Discover how this process enhances aluminum profiles for various applications.

Anodizing improves corrosion resistance in aluminum profiles by creating a thick oxide layer that acts as a barrier against moisture and corrosive agents, enhancing durability and longevity.

The Anodizing Process and Its Role

Anodizing is an electrochemical process that converts the metal surface into a decorative, durable, corrosion-resistant, anodic oxide finish.

This finish not only enhances the appearance of aluminum but significantly boosts its resistance to corrosion.

The process involves immersing the aluminum in an acid electrolyte bath and passing an electric current through it. This reaction causes the aluminum to oxidize, forming a thick layer of aluminum oxide on its surface. This layer acts as a barrier, preventing moisture and corrosive agents from penetrating the aluminum itself.

- Thickness of the Oxide Layer: The thickness of the anodized layer can be controlled by adjusting the duration of the anodizing process, leading to greater protection against corrosion.

- Environmental Factors: Factors like temperature and chemical composition of the electrolyte bath can also influence the quality and effectiveness of the anodized layer.

For more information on the anodizing process, check out this detailed guide.

Corrosion Resistance Mechanisms

The anodized layer provides several mechanisms that enhance corrosion resistance:

- Barrier Effect: The anodized layer acts as a physical barrier, preventing corrosive substances from reaching the underlying aluminum.

- Self-Healing Properties: If the surface is scratched or damaged, the aluminum oxide layer has the ability to reform when exposed to air, effectively sealing any breaches.

- Electrochemical Stability: Anodized aluminum maintains a higher electrochemical stability compared to untreated aluminum, which is particularly beneficial in harsh environments.

| Mechanism | Description |

|---|---|

| Barrier Effect | Prevents corrosive agents from penetrating the metal surface. |

| Self-Healing | The oxide layer can reform when damaged, sealing scratches. |

| Electrochemical Stability | Reduces susceptibility to galvanic corrosion compared to untreated aluminum. |

Applications in Various Industries

The enhanced corrosion resistance from anodizing makes aluminum profiles suitable for various applications:

- Construction: Used in building facades, windows, and doors where durability is essential.

- Automotive: Enhances the longevity of vehicle components exposed to harsh weather conditions.

- Consumer Electronics: Protects electronic devices from moisture and damage, ensuring reliability over time.

As David’s company specializes in outdoor equipment like aluminum alloy car travel tents, the use of anodized aluminum ensures that their products remain durable even in challenging weather conditions. Learn more about aluminum applications.

Comparing Anodized Aluminum with Other Materials

When considering materials for projects requiring corrosion resistance, anodized aluminum stands out:

- Weight: Lighter than stainless steel, making it ideal for portable products.

- Cost: Generally more affordable than other corrosion-resistant options like titanium.

- Aesthetics: Available in various colors and finishes to meet design needs without sacrificing performance.

For a comparison with other materials like stainless steel or plastic, see this comparison chart.

What are the aesthetic advantages of using anodized aluminum in electronics?

Discover how anodized aluminum enhances both functionality and aesthetics in electronics, making it a popular choice among designers and manufacturers.

Anodized aluminum offers several aesthetic advantages in electronics, including enhanced visual appeal through customizable finishes, improved durability, eco-friendliness, and a sophisticated brand image.

Visual Appeal of Anodized Aluminum

Anodized aluminum is renowned for its striking visual qualities. The anodizing process enhances the natural beauty of aluminum, creating a surface that can be smooth, satin, or even textured.

This versatility allows designers to choose finishes that best align with their brand identity. Additionally, anodized surfaces can be dyed in various colors, providing endless possibilities for customization. By opting for vibrant colors, manufacturers can create products that stand out in a crowded market.

Enhanced Durability and Longevity

While aesthetics are crucial, durability cannot be overlooked. Anodized aluminum is significantly more resistant to scratches, corrosion, and wear compared to untreated aluminum. This means that the attractive appearance of electronic devices can be preserved over time.

Here’s a quick comparison of anodized vs untreated aluminum:

| Property | Anodized Aluminum | Untreated Aluminum |

|---|---|---|

| Scratch Resistance | High | Low |

| Corrosion Resistance | Excellent | Poor |

| Color Options | Extensive | Limited |

Eco-Friendly Options

In today’s market, sustainability is a key selling point. Anodizing is an eco-friendly process, as it utilizes non-toxic dyes and produces minimal waste. Companies like David’s can leverage this aspect to appeal to environmentally conscious consumers. Furthermore, anodized aluminum is fully recyclable, reinforcing its position as a sustainable choice in the electronics industry. For more on sustainable manufacturing practices, check this out!

Sophisticated Brand Image

Utilizing anodized aluminum can elevate the perceived value of a product. Consumers often associate high-quality finishes with premium brands. Therefore, incorporating anodized components into electronics not only enhances their look but also contributes to a sophisticated brand image. This perception is crucial for companies looking to establish themselves in competitive markets.

By aligning product design with consumer expectations, businesses can enhance customer loyalty and drive sales. Exploring brand positioning strategies can further help companies like David’s refine their market approach.

How does anodized aluminum compare to other materials used in electronics?

Explore the comparative advantages of anodized aluminum against other materials used in electronics, focusing on key attributes such as durability, thermal management, and aesthetics.

Anodized aluminum offers superior durability, excellent thermal conductivity, and effective EMI shielding compared to materials like stainless steel or plastic, making it ideal for high-performance electronic applications.

Durability and Wear Resistance

Anodized aluminum is well-regarded for its superior durability. The anodization process creates a thick layer of aluminum oxide on the surface, which significantly enhances wear resistance compared to untreated aluminum and even stainless steel.

This increased durability ensures that electronic components can withstand harsh environments, making anodized aluminum suitable for outdoor applications, such as in car travel tents.

| Material | Durability | Wear Resistance | Applications |

|---|---|---|---|

| Anodized Aluminum | High | Excellent | Outdoor electronics, housings |

| Stainless Steel | Medium | Moderate | General electronics, automotive |

| Plastic | Low | Poor | Low-cost electronics, single-use items |

Thermal Conductivity

When it comes to thermal performance, anodized aluminum stands out due to its excellent thermal conductivity. This property is crucial for heat-sensitive electronic components that need efficient heat dissipation to prevent overheating.

In contrast, materials like plastic and certain composites lack the thermal management capabilities of anodized aluminum, often leading to performance issues in electronics. For more on thermal management materials, check this resource.

Electromagnetic Interference (EMI) Shielding

Another significant advantage of anodized aluminum is its ability to provide some degree of EMI shielding. The anodized layer can help mitigate electromagnetic interference, ensuring stable operation of electronic devices.

While materials like copper offer better EMI shielding, anodized aluminum strikes a balance between performance and weight, making it a preferred choice in many electronic applications. Learn more about EMI shielding techniques here.

Aesthetic Appeal

In consumer electronics, aesthetics are as crucial as functionality. Anodized finishes not only enhance the appearance of electronic products but also provide a protective layer that resists scratches and corrosion.

This combination of aesthetics and durability makes anodized aluminum highly desirable for high-end consumer electronics. For insights on design trends in electronics, visit this link.

Corrosion Resistance

Anodized aluminum exhibits excellent corrosion resistance, particularly when compared to untreated aluminum. The anodization process creates a protective layer that prevents oxidation and degradation over time, especially in challenging environments.

In contrast, materials like mild steel can rust easily if not coated properly, whereas stainless steel offers some resistance but at a higher cost and weight. For an in-depth comparison of corrosion resistance in materials, check this article.

What considerations should manufacturers keep in mind when using anodized aluminum?

Anodized aluminum offers numerous benefits, but manufacturers need to consider specific factors to optimize its use in their products. Here are key considerations for successful implementation.

Manufacturers using anodized aluminum should consider its thermal conductivity, EMI shielding, aesthetics, wear resistance, environmental impact, cost vs. quality balance, and compliance with industry standards.

Understanding Anodized Aluminum

When considering anodized aluminum, manufacturers must appreciate the unique properties imparted by the anodizing process. This electrochemical process enhances the natural oxide layer on aluminum, providing superior corrosion resistance and improved surface hardness. It is critical to grasp how this affects the performance and durability of the final product.

Thermal Conductivity

Anodized aluminum exhibits excellent thermal conductivity, making it suitable for applications in heat-sensitive environments, such as electronic components. For instance, the heat dissipation capabilities can be particularly advantageous in high-performance devices where overheating is a concern. Manufacturers should assess the thermal management needs of their designs to fully leverage this property.

Electromagnetic Interference (EMI) Shielding

Another vital consideration is the anodized surface’s ability to offer protection against electromagnetic interference (EMI). This shielding is crucial for maintaining the stability and performance of electronic devices. When designing products that incorporate sensitive electronic components, understanding how anodized aluminum can contribute to EMI shielding should be a priority.

Aesthetic Appeal

In addition to functional benefits, anodized aluminum provides a sleek and attractive finish that can enhance product appeal. The variety of color options available through anodizing allows manufacturers to meet aesthetic requirements without compromising on durability. Combining aesthetics with functionality is essential for consumer-oriented products.

Wear and Tear Resistance

Anodized coatings significantly improve the wear and tear resistance of aluminum components. This is particularly important for products that experience frequent handling or exposure to harsh environments. A table summarizing these benefits can help clarify how anodized aluminum compares to other materials:

| Property | Anodized Aluminum | Other Materials |

|---|---|---|

| Corrosion Resistance | Excellent | Varies |

| Thermal Conductivity | High | Moderate |

| Aesthetic Options | Wide variety | Limited |

| Wear Resistance | Superior | Moderate to Low |

Environmental Considerations

Manufacturers must also consider the environmental impact of anodizing processes. Anodizing typically involves fewer hazardous materials compared to other finishing methods. However, it’s important to work with suppliers who prioritize sustainable practices in their anodizing processes. For insights into environmentally friendly anodizing practices, check out sustainable anodizing solutions.

Cost vs. Quality

While anodizing provides several advantages, manufacturers should weigh the costs associated with this process against the desired quality of their products. It’s essential to find a balance that aligns with both budget constraints and quality expectations, particularly for products designed for demanding environments.

Compliance with Standards

Finally, adhering to industry standards for anodized aluminum is crucial. Manufacturers should familiarize themselves with relevant regulations to ensure that their products meet all necessary safety and performance criteria. To learn more about these standards, explore aluminum anodizing compliance guidelines.

By keeping these considerations in mind, manufacturers can effectively leverage anodized aluminum in their products, resulting in enhanced durability, aesthetic appeal, and overall performance.

Conclusion

Anodized aluminum offers enhanced durability, thermal management, EMI shielding, and aesthetic appeal for electronic products, making it a preferred choice in various industries.

![Product image of [Description of the product, including key features or aesthetic details]](https://sinoextrud.com/wp-content/uploads/product-image-of-description-of-the-product-including-key-features-or-aesthetic-details.webp 1024w, https://sinoextrud.com/wp-content/uploads/product-image-of-description-of-the-product-including-key-features-or-aesthetic-details-768x768.webp 768w, data:image/webp;base64,UklGRpoAAABXRUJQVlA4II4AAAAwAgCdASoMAAwAAQAaJZQCdAEUuTFsD+XmYAD+2EV1d8fVpbzx3XU3cUn8pkxycQSL/uC/91/YxrxSC9WP+PrZ28m7gvO1J6kP95mwggbOprj2OkpOWzWoT2NTKtsXhYjWNagMhz7BkK5H0fxfBf4Nc7Z59KfJd8Tfp+ei2UR9VsE1VlsIc4U+bhvl5gAA 12w, https://sinoextrud.com/wp-content/uploads/product-image-of-description-of-the-product-including-key-features-or-aesthetic-details-600x600.webp 600w)