Can the heat sink be machined with ±0.1 mm tolerance?

Ever had a heat sink that just almost fit, but not quite? Tolerances matter—a lot. In some designs, even a 0.2 mm deviation can ruin contact or block assembly.

Yes, most aluminum heat sinks can be machined to ±0.1 mm tolerance using standard CNC processes, especially on critical surfaces.

Let’s go deeper into what this really means, how it’s done, and where the limits are when working with aluminum heat sinks.

What processes ensure tight machining tolerance in heat sinks?

Machining to tight tolerances is not just about the cutting tool. It involves the entire chain—from material prep to final inspection.

Tight tolerance machining in heat sinks relies on CNC milling, precision fixturing, controlled environments, and multi-step calibration.

Here are the main steps and technologies used:

Precision Machining Methods

| Process | Tolerance Range | Application |

|---|---|---|

| CNC milling | ±0.05–0.10 mm | Most flat and structural surfaces |

| Wire EDM | ±0.01–0.05 mm | Rare for heat sinks; complex profiles |

| Surface grinding | ±0.01–0.03 mm | Flatness-critical bases |

| Diamond turning | ±0.005 mm | Optical or ultra-flat surfaces |

Supporting Techniques

- High-quality fixtures prevent vibration and shift.

- Coolant control maintains thermal stability.

- Multi-axis CNCs allow better angular and compound tolerance management.

We once supplied a batch of custom CPU heat sinks where the mounting base had to be ±0.05 mm flat across 80 mm. It took triple-checking with surface grinding and CMM verification, but the end result was perfect fit and 20% lower contact resistance.

CNC machining can achieve ±0.1 mm tolerance for heat sinks under controlled conditions.True

Standard 3-axis and 5-axis CNCs are capable of such tolerances.

Heat sink surfaces cannot be machined to better than ±1.0 mm tolerance.False

Modern CNC equipment achieves much tighter tolerances than that.

Is ±0.1 mm tolerance viable for large profiles?

The bigger the part, the harder it is to hold tight tolerances. Warping, vibration, and tool drift all start to matter more.

Yes, ±0.1 mm tolerance is possible for large profiles, but it requires multi-step machining, careful fixturing, and post-machining inspection.

What Makes Large Parts Challenging

| Factor | Problem |

|---|---|

| Length | More thermal expansion |

| Flatness | Hard to keep base even |

| Rigidity | Higher risk of chatter or deflection |

| Clamping | May induce internal stress |

Solutions

- Break long parts into segments for machining

- Use reference edges and datum alignment

- Machine from both ends using precision jigs

- Allow parts to rest/stabilize before finishing

- Check mid-process with CMM or dial gauges

We worked on a 500 mm wide heat sink for industrial LED arrays. Holding ±0.1 mm flatness across the base needed three operations, including thermal rest periods and surface lapping.

Tight tolerance can be achieved even on large heat sink profiles with the right processes.True

Proper machine setup, thermal control, and fixturing make this possible.

Large heat sinks can never meet tight tolerances due to their size.False

It’s difficult, but not impossible with careful machining.

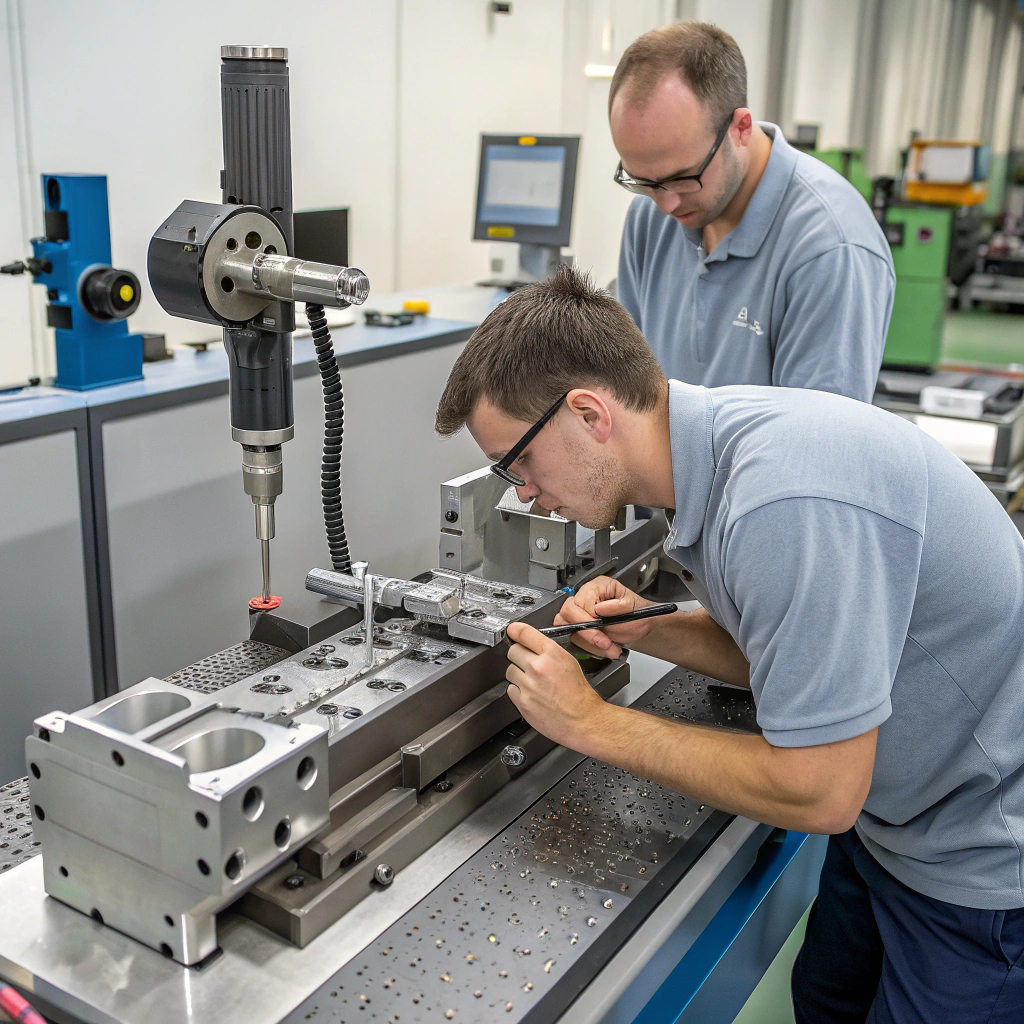

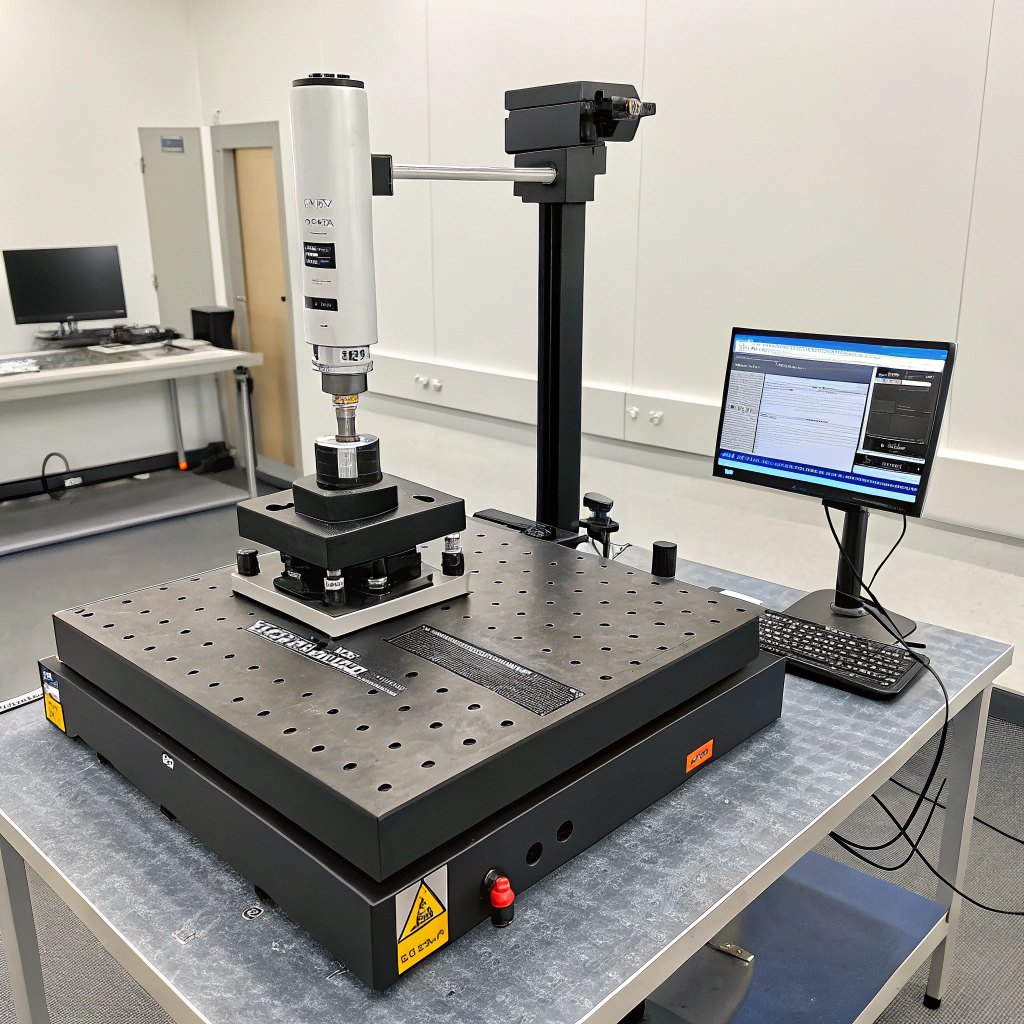

What tools are used for verifying heat sink tolerances?

Measuring tight tolerances is just as important as making them. If you can’t verify ±0.1 mm, you can’t claim it.

Heat sink tolerances are verified using calipers, micrometers, height gauges, coordinate measuring machines (CMMs), and surface flatness tools.

Tools and Their Use Cases

| Tool | Accuracy | Application |

|---|---|---|

| Vernier calipers | ±0.02 mm | Length, width, slot measurements |

| Micrometers | ±0.01 mm | Small thicknesses or step heights |

| Height gauges | ±0.01 mm | Depth and profile step differences |

| Dial indicator | ±0.001 mm | Runout or flatness |

| CMM (3D) | ±0.001–0.005 mm | High-end dimensional mapping |

| Surface plate + gauge block | ±0.002 mm | Flatness checks on base areas |

We use granite surface plates combined with height gauges to test for warping in large extrusions. For tight cavity work, we rely on a Mitutoyo CMM for 3D mapping.

Coordinate measuring machines (CMMs) are used to verify tight tolerances in heat sinks.True

They provide precise 3D measurements within micron accuracy.

Rulers and tape measures are enough to verify ±0.1 mm tolerance.False

That level of tolerance requires specialized precision instruments.

How do you control quality at micron-level precision?

Even small errors during production can wreck tight tolerances. Quality control at micron scale means full process discipline.

Micron-level quality is managed through calibrated machines, stable environments, and multi-stage inspection.

Quality Assurance Workflow

-

Material control

We inspect incoming material dimensions and hardness. -

Tool calibration

All CNC and inspection tools are calibrated monthly. -

Thermal management

Machining is done in temperature-controlled rooms. -

In-process checks

Operators check dimensions after roughing and before finishing. -

Final inspection

Every batch goes through a QA checklist using micrometers and CMM. -

Documentation

We log every measurement for traceability.

Sample Quality Control Table

| Step | Inspection Tool | Frequency | Pass Criteria |

|---|---|---|---|

| Base flatness | Dial indicator on granite | Every 10 pcs | ≤0.08 mm |

| Mounting holes | Height gauge | 100% | ±0.05 mm |

| Surface finish | Visual + test card | Random | Ra ≤ 1.6 µm |

| Profile thickness | Micrometer | 100% | ±0.1 mm |

When producing heatsinks for a Japanese EV maker, we had to hold ±0.03 mm hole spacing over 250 mm length. That required automated checking every 5 parts and corrective offset routines in the CNC program.

Maintaining micron-level tolerance requires tool calibration, stable environments, and in-process inspection.True

All stages of machining and QC must be tightly controlled.

Micron-level tolerance can be maintained without regular inspection or environment control.False

Even small thermal or tool errors can ruin such precision.

Conclusion

Tight tolerance machining in aluminum heat sinks is completely achievable—even down to ±0.1 mm or better. But it requires the right tools, skilled operators, and strict control at every step. Ask your manufacturer what they can guarantee, and how they measure it.