CNC Machining Saudi Arabia: Manufacturers & Industry Guide

Part 1: Market Size and Growth

I see Saudi CNC machining moving fast with Vision 2030 at its back. Local buyers want quality parts for energy, defense, mobility, and construction. Exporters also see Riyadh as a bridge to the wider GCC. Precision work now matters as much as volume, and buyers reward repeatable tolerances.

In the past, most complex parts came from overseas. Now I watch more of that work shift into local machine shops and OEM hubs. The push to localize supply chains is real, and it touches castings, forgings, and final machining. Digital workflows, metrology, and clean manufacturing now sit on every serious buyer’s checklist.

Policy and investment shape the curve. Big industrial parks, such as SPARK and Modon clusters, pull in international players and SMEs. Universities and training centers feed fresh machinists who learn on modern equipment. This mix speeds up certification, reduces lead times, and builds trust with global primes.

Part 2: Leading Companies

Saudi Mechanical Industries (SMI)

SMI is a Dammam-based precision manufacturer with deep local roots. The company runs machining, fabrication, and finishing inside Saudi industrial zones. It works under an audited quality system with ISO 9001:2015, ISO 14001, and ISO 45001. I like that their certifications cover quality, environment, and safety together.

SMI’s portfolio spans engineered components, pump parts, gear-drive items, and custom assemblies. Teams manage design support, reverse engineering, and quality control, which helps with complex change orders. Main sectors include oil and gas, utilities, and building systems. The firm highlights that a large share of manufacturing steps happen in-kingdom.

SLB (formerly Schlumberger) – SPARK Manufacturing Centers

SLB operates world-class manufacturing centers inside King Salman Energy Park. These sites support the IKTVA localization program and regional exports. The facilities produce well completions hardware and high-spec valve technologies used across the energy chain. This is a strong signal of advanced machining and assembly moving onshore.

The centers blend machining, testing, and qualification under one roof. Customers in upstream, midstream, and downstream benefit from shorter lead times. SLB’s long presence in the Kingdom supports training, supplier development, and tech transfer. These hubs anchor a reliable local ecosystem for critical components.

Siemens Energy – Dammam Hub

Siemens Energy’s Dammam Hub manufactures and services key power technologies. The site has expanded under recent contracts tied to large gas power projects. Local content rises as the hub takes on more component manufacturing and repairs. That shift builds practical experience for complex machining and assembly.

The hub supports plant upgrades and life-cycle service for turbines and auxiliaries. Typical work involves precision machining, balancing, and advanced inspection. End markets include utilities, industrial power, and cogeneration sites. The model cuts downtime and keeps critical assets productive.

Baker Hughes – Industrial & Energy Technology in Dammam

Baker Hughes runs a major manufacturing footprint in Dammam’s industrial city. The company is expanding capacity to support Aramco’s pipeline and gas projects. Local teams build and service high-value rotating equipment and subassemblies. This is high-mix work that relies on tight CNC and rigorous QA.

These programs bring machining, coating, and testing closer to the field. I see strong demand for fixtures, metrology, and traceability in these lines. Energy, petrochemicals, and water projects all pull from the same precision skill base. Investments show confidence in Saudi industrial depth.

| Company | Founded | Core Products | Industries | Certifications |

|---|---|---|---|---|

| Saudi Mechanical Industries (SMI) | 1980s (Saudi), roots in local industry | Engineered components, pump and gear parts, custom machining | Oil & Gas, Utilities, Building Systems | ISO 9001, ISO 14001, ISO 45001, UL/FM |

| SLB (Schlumberger) – SPARK | 1926 (global); KSA centers 2020–2022 | Completions hardware, GROVE/ORBIT valves, assemblies | Upstream, Midstream, Downstream | Global O&G standards; IKTVA participation |

| Siemens Energy – Dammam Hub | 2020 (global spinoff); KSA hub expanded 2025 | Power components, turbine service, precision repairs | Utilities, Industrial Power | OEM standards; project QA systems |

| Baker Hughes – Dammam | 1907 (global); KSA expansions 2024–2025 | Rotating equipment modules, compressor components | Gas networks, Pipelines, Petrochemicals | OEM standards; Aramco-qualified programs |

Part 3: Trade Shows and Industry Events

MACTECH Saudi Arabia

MACTECH Saudi Arabia is a focused show for CNC metalworking and machine tools. It gathers suppliers of machining centers, cutting, welding, and industrial tools. The 2025 edition took place at RICEC in Riyadh with a clear push on automation. I use this show to track who offers local service and spares.

The floor mixes live demos with training talks. I meet control vendors, metrology teams, and safety suppliers in one hall. The format is practical and geared to plant engineers. It is a strong venue to benchmark total cost of ownership.

Riyadh International Industry Week (RIIW)

RIIW is a large umbrella event that hosts multiple specialized industrial shows. In 2025 it ran May 12–15 at RICEC and featured 524+ exhibitors from 20 countries. The week pulled in plastics, packaging, smart manufacturing, and logistics audiences. It is the best snapshot of Saudi industrial momentum I have seen.

I like the mix of ministry-led keynotes and vendor workshops. Buyers compare automation projects and discuss skills with educators. Many booths highlight local partnerships and in-kingdom assembly. The content feels practical, not just promotional.

| Event | Date | Location | Highlights |

|---|---|---|---|

| MACTECH Saudi Arabia | Jan 21–23, 2025 | RICEC, Riyadh | CNC machine tools, cutting, welding, automation, live demos |

| Riyadh International Industry Week | May 12–15, 2025 | RICEC, Riyadh | 524+ exhibitors, smart manufacturing tracks, supply chain focus |

Part 4: Impact of Global Trade Policies

Trade policy shapes machine shops as much as toolpaths do. Vision 2030 and the IKTVA program push local content and skills transfer. International OEM hubs in Dammam and SPARK reflect that policy in action. Localization is no longer a slogan; it drives purchase orders and hiring.

Export controls and sanctions also matter. Some advanced machine tools or materials need special clearances. Shops that plan ahead on compliance avoid delays at the port. I build buffers into timelines for critical imports and spares.

I also see opportunity in regional trade ties. GCC neighbors buy maintenance and upgrade services from Saudi hubs. Global primes like SLB, Siemens Energy, and Baker Hughes bring supplier networks with them. This raises quality baselines and opens doors for certified local vendors.

Part 5: Conclusion

I believe Saudi CNC machining is entering a strong growth phase. Energy, defense, and infrastructure projects create steady demand. International hubs anchor standards and training while local firms scale up. If shops keep investing in metrology, CAM, and people, the curve stays up.

Risks still exist. Supply chains can tighten, and skilled labor remains scarce. Certification takes time and discipline. Shops that master quality systems and plan for compliance will win the bigger work.

Recommended Reading:

CNC Machining Brazil

CNC Machining Canada

CNC Machining Spain

CNC Machining Australia

CNC Machining Mexico

CNC Machining Indonesia

CNC Machining Turkey

CNC Machining Netherlands

What is a thermal break window? Is it worth for home?

Telescopic Tube Manufacturer

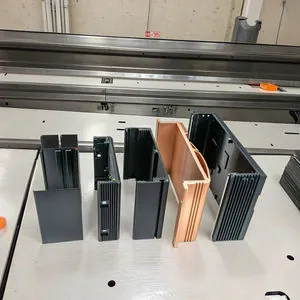

Aluminium Extrusion Enclosure

6063T6 Aluminium Profile Corner