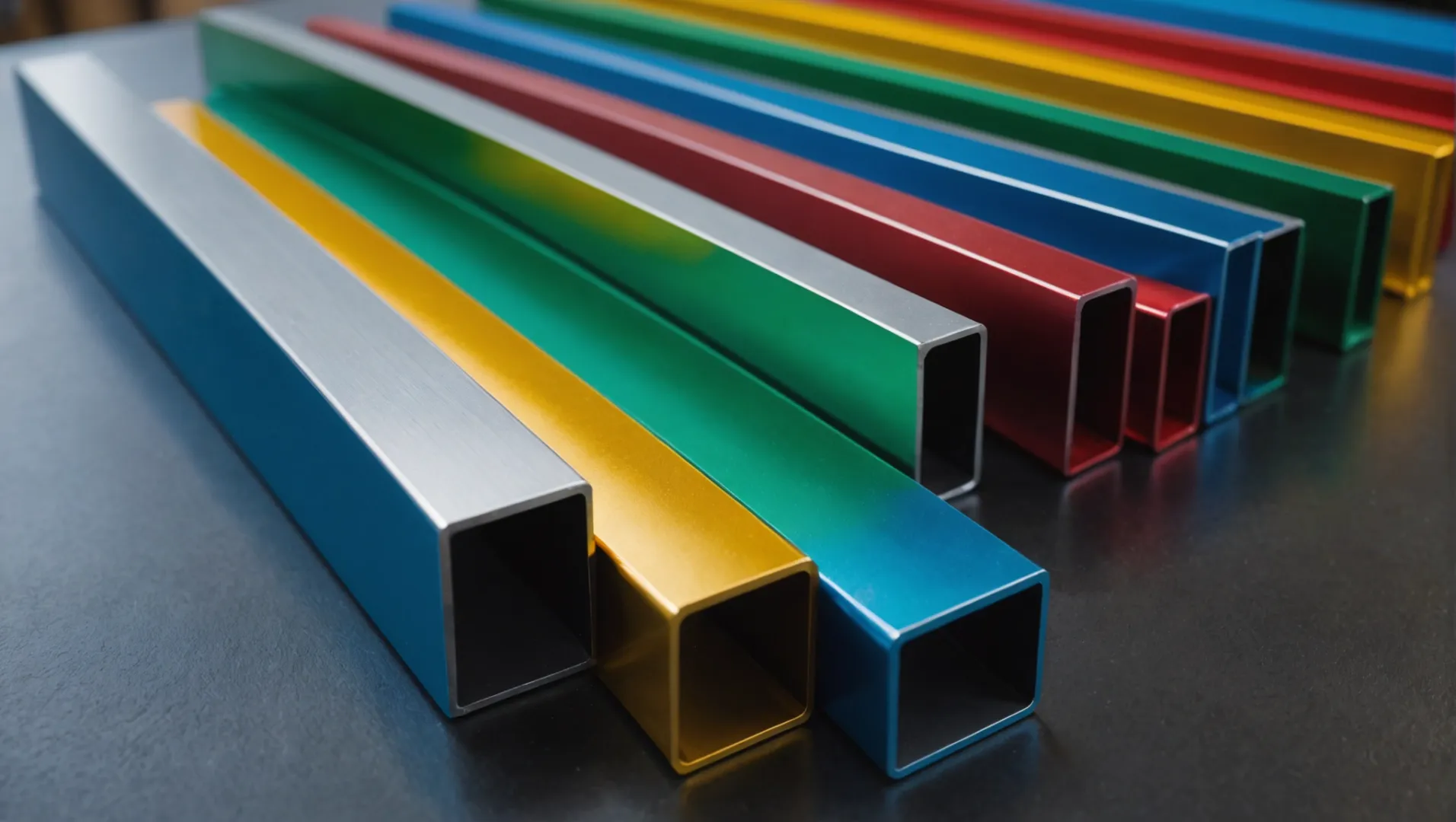

How Can Aluminium Profiles Be Oxidized in Various Colours?

Aluminum profiles offer a unique blend of durability and versatility, but what truly elevates their charm? It’s the vibrant colors achieved through oxidation!

Aluminum profiles can be oxidized in various colors primarily through the anodization process, which involves electrolytic passivation. This technique allows for a wide range of finishes and colors while improving the material’s durability and corrosion resistance.

But there’s more beneath the surface! Join me as we explore the intricate steps of anodization and discover how each phase contributes to the stunning results we see.

Anodized aluminum profiles enhance durability and color variety.True

Anodization improves corrosion resistance and allows for vibrant colors.

What Are the Key Steps in the Anodization Process?

Discover how anodization transforms aluminum, enhancing its durability and aesthetic appeal.

The anodization process involves cleaning, pre-treatment, anodizing, coloring, and sealing. Each step is crucial for ensuring the aluminum’s enhanced surface durability and color uniformity.

The anodization process for aluminum is a methodical and technical procedure that enhances both the physical properties and aesthetic appeal of the material. Understanding each step is essential for achieving the desired finish and durability.

Step 1: Cleaning

The initial phase involves thoroughly cleaning the aluminum to remove any impurities such as dirt, grease, or previous coatings. This is typically done using a series of alkaline or acidic solutions that prepare the surface for subsequent treatments. Ensuring a clean surface is critical for achieving a uniform anodized layer.

Step 2: Pre-Treatment

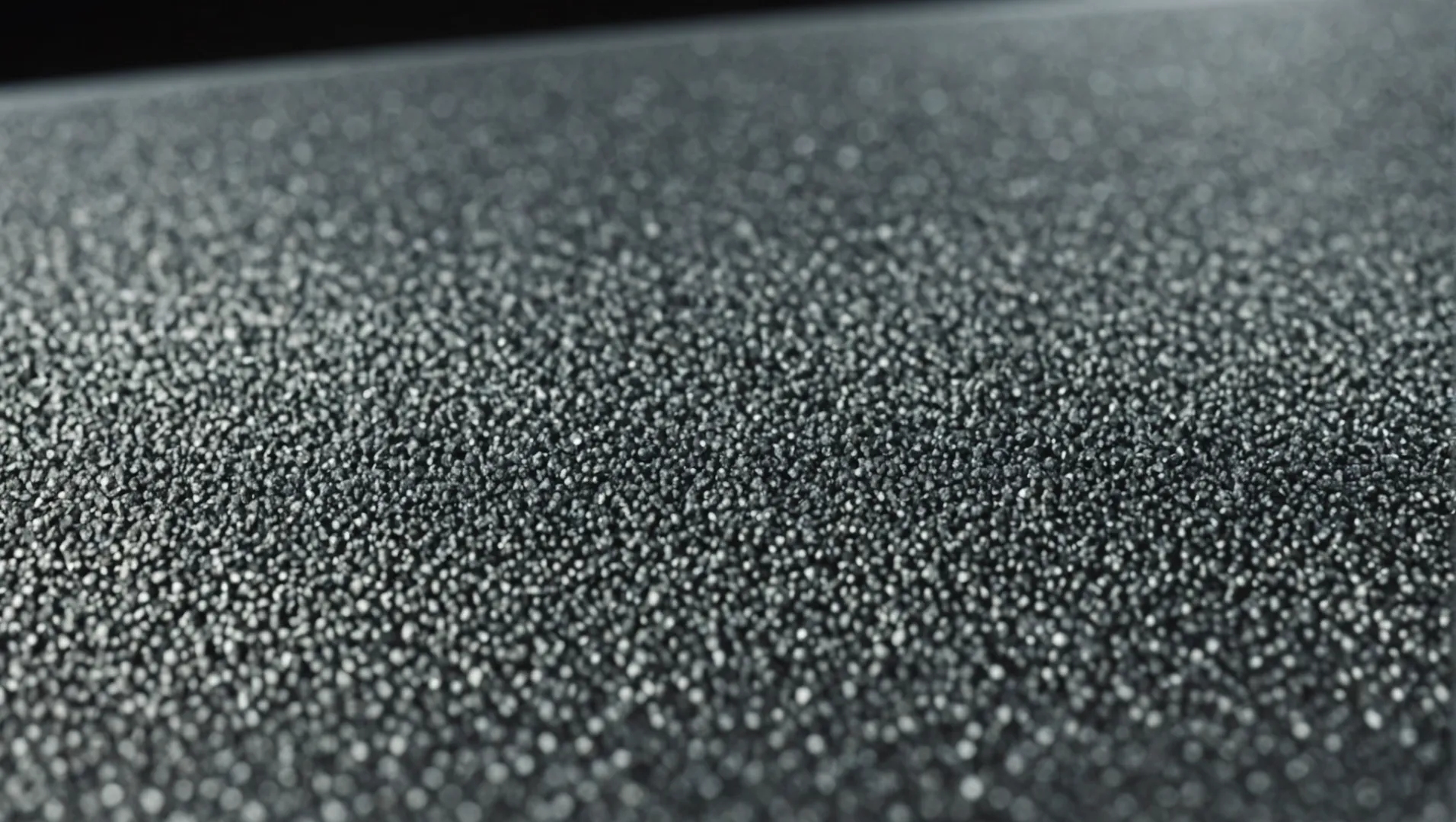

After cleaning, pre-treatment techniques such as sandblasting1 or polishing are applied to create specific finishes. Sandblasting imparts a matte texture, ideal for reducing glare and enhancing adhesion, while polishing results in a high-gloss, reflective surface that is popular for decorative applications.

Step 3: Anodizing

The core of the process, anodizing involves immersing the aluminum in an electrolyte bath and applying an electric current. This step creates a thick oxide layer on the surface, significantly enhancing corrosion resistance. The thickness of this layer can be controlled by adjusting the voltage and time in the bath.

Step 4: Coloring

Anodized aluminum can be colored during or after the anodizing step. Electrolytic coloring deposits metal salts into the porous anodized layer, offering a range of hues from subtle tones to vibrant colors. Alternatively, dyeing involves immersing the anodized aluminum in organic dyes.

| Coloring Technique | Description |

|---|---|

| Electrolytic Coloring | Uses metal salts for stable color options |

| Dyeing | Involves organic dyes for vibrant hues |

Step 5: Sealing

The final stage of anodization is sealing, where pores created during anodizing are closed to lock in color and improve surface hardness. This step prevents fading and enhances the overall wear resistance of the aluminum.

Understanding these steps allows manufacturers to tailor anodized finishes2 to specific applications, from architectural components to consumer electronics.

Cleaning is the first step in anodization.True

Cleaning removes impurities, crucial for a uniform anodized layer.

Sealing is not necessary in anodization.False

Sealing locks in color and enhances surface hardness, preventing fading.

How Does Sandblasting Enhance Anodized Aluminum?

Sandblasting transforms anodized aluminum by creating a uniform, textured finish, enhancing both aesthetics and durability.

Sandblasting improves anodized aluminum by providing a matte finish, increasing surface adhesion, and preparing it for further anodization processes.

The Role of Sandblasting in Anodizing

Sandblasting is a pivotal pre-treatment process in the world of anodized aluminum. Before the anodization process, sandblasting involves the high-speed projection of abrasive materials, like sand, onto the aluminum surface. This action creates a uniform matte finish, which enhances the aesthetic appeal of the metal. The textural contrast it provides can be particularly beneficial for applications demanding a modern, minimalist look.

Enhancing Adhesion and Durability

One of the key benefits of sandblasting is its ability to improve surface adhesion. By roughening the aluminum surface, sandblasting increases the bonding area for the anodic film, leading to a more robust and durable anodized layer. This enhancement is crucial for applications where additional coatings or paint are applied after anodizing. The improved adhesion reduces the likelihood of peeling or flaking, thus extending the product’s lifespan.

Preparing for Complex Anodizing Processes

Anodized aluminum can undergo various treatments post-sandblasting, such as bright finishing3 or brushed anodizing4. Sandblasting prepares the aluminum for these treatments by creating a consistent base. This preparation ensures that subsequent processes yield a uniform color and finish across the entire surface, which is vital for maintaining high-quality standards in consumer products.

Applications in Diverse Industries

The benefits of sandblasting anodized aluminum are widely recognized across several industries. For instance, in the automotive sector, sandblasted anodized components are valued for their corrosion resistance and aesthetic appeal. Similarly, in architecture, such treatments can provide sleek finishes for building facades or interior elements. The electronics industry also leverages these properties to create durable and visually appealing devices.

Case Studies and Examples

Consider an architectural firm aiming to design a contemporary office building. Using sandblasted anodized aluminum for window frames or external cladding can offer both functional benefits—like weather resistance—and an attractive modern appearance. Likewise, consumer electronics companies often choose this finish for products that need to withstand frequent handling while maintaining a premium look.

To explore more about how these processes are integrated into different industries, you can delve into detailed case studies and examples from leading manufacturers and designers.

Sandblasting improves adhesion of anodized aluminum.True

Sandblasting roughens the surface, increasing bonding area for anodic film.

Anodized aluminum cannot be sandblasted for a matte finish.False

Sandblasting is used specifically to create a uniform matte finish.

What Are the Benefits of Different Anodized Finishes?

Anodized finishes not only enhance the visual appeal of aluminum profiles but also significantly improve their functionality.

Different anodized finishes offer benefits like improved durability, aesthetic appeal, corrosion resistance, and ease of maintenance. Each finish type—whether sandblasted, polished, or brushed—provides unique attributes suitable for specific applications across various industries.

Enhancing Durability and Corrosion Resistance

One of the primary advantages of anodized finishes is the increased durability they provide to aluminum profiles. Anodizing creates a protective layer that is bonded to the aluminum, offering excellent resistance to wear and corrosion. This makes anodized aluminum ideal for outdoor applications where exposure to harsh elements is a concern.

For example, in construction materials5, the enhanced resistance extends the lifespan of structural components, reducing maintenance needs and costs over time.

Aesthetic Versatility and Customization

The range of available finishes—from high-gloss polished to subtle matte—allows for significant aesthetic versatility. These finishes can be customized to match any design requirement, making them highly desirable for architectural projects and consumer products.

- Polished Anodizing: Known for its mirror-like sheen, this finish is often used in luxury goods and high-end electronics.

- Brushed Anodizing: Offers a sophisticated look with a textured appearance, making it popular in appliance manufacturing.

Improved Surface Adhesion

Certain anodized finishes, such as sandblasted, enhance surface adhesion, which is particularly beneficial for subsequent coatings or paints. This property is advantageous in industries that require further customization or branding on aluminum profiles, such as automotive manufacturing6.

| Finish Type | Benefits |

|---|---|

| Sandblasted | Enhanced adhesion for coatings |

| Polished | High aesthetic value with a glossy finish |

| Brushed | Textured appearance with moderate reflectivity |

Easy Maintenance and Longevity

Anodized finishes are not only durable but also easy to maintain. They resist dirt and fingerprints better than untreated surfaces, making them suitable for high-touch environments like public buildings and transport hubs. Additionally, the anodizing process locks in colors and finishes, ensuring they remain vibrant over time without frequent maintenance.

Industry-Specific Applications

Different industries leverage these benefits in various ways. For instance, electronics manufacturers may choose bright finishes to enhance product appeal, while industrial sectors often select matte or iron gray finishes for their non-reflective properties.

By understanding the specific benefits each anodized finish offers, businesses can make informed decisions that align with their operational needs and aesthetic goals.

Anodized finishes increase aluminum's corrosion resistance.True

Anodizing creates a protective layer, enhancing resistance to corrosion.

Polished anodizing is used in high-end electronics for its matte finish.False

Polished anodizing is known for its mirror-like sheen, not a matte finish.

Which Industries Benefit Most from Colored Anodized Aluminum?

Colored anodized aluminum offers unique aesthetic and functional benefits, transforming various industries with its versatility and durability.

Industries benefiting most from colored anodized aluminum include architecture, automotive, consumer electronics, and interior design. This material enhances aesthetics, provides corrosion resistance, and supports sustainability goals.

Architecture and Construction

Colored anodized aluminum is a popular choice in the architecture7 and construction industry due to its aesthetic flexibility and durability. Architects often use it for building facades, window frames, and roofing. The material’s range of colors allows for creative design solutions that stand the test of time. Its corrosion-resistant nature makes it ideal for exterior applications, ensuring longevity and reduced maintenance costs.

Automotive Industry

In the automotive industry8, colored anodized aluminum is used in both exterior and interior components. The material offers a lightweight alternative to traditional metals, improving fuel efficiency without compromising strength or safety. Exterior trims, wheels, and interior accents benefit from the vibrant colors and finishes available through anodization. This not only enhances visual appeal but also adds a layer of protection against environmental factors.

Consumer Electronics

Colored anodized aluminum is extensively used in consumer electronics9. Its sleek, modern appearance makes it a favorite for devices like smartphones, laptops, and tablets. The material’s ability to dissipate heat effectively while maintaining a premium look makes it a top choice for manufacturers aiming for both functionality and style. The anodization process also improves scratch resistance, which is crucial for products that are frequently handled.

| Industry | Application | Benefits |

|---|---|---|

| Architecture | Facades, window frames | Aesthetic versatility, corrosion resistance |

| Automotive | Trims, wheels | Lightweight, fuel-efficient |

| Consumer Electronics | Smartphones, laptops | Heat dissipation, scratch resistance |

Interior Design

Interior designers leverage colored anodized aluminum for its ability to offer a high-end finish that complements modern aesthetics. The material is often used in furniture, light fixtures, and decorative pieces. Its variety of finishes—from polished to matte—allows designers to achieve the desired visual impact while ensuring durability in high-traffic areas.

The versatility of colored anodized aluminum makes it indispensable across these industries, offering solutions that meet both practical needs and creative aspirations.

Colored anodized aluminum enhances automotive fuel efficiency.True

It is lightweight, improving fuel efficiency without compromising strength.

Anodized aluminum is rarely used in consumer electronics.False

It's extensively used for its sleek appearance and heat dissipation.

Conclusion

Mastering the anodization process allows you to select the perfect finish for your aluminum profiles, balancing aesthetics with functionality. Dive into the details to achieve outstanding results in your projects.

-

Learn how sandblasting improves adhesion and prepares surfaces effectively.: Sandblasting is to use compressed air as the power to form a high-speed jet beam, spraying the abrasive (steel sand, brown corundum, glass beads, emery, etc.) … ↩

-

Explore diverse anodized finishes for tailored applications.: Most anodizing on machined parts are of two commonly specified types: Type II (or “regular”) sulfuric anodizing and Type III Hardcoat or “hard” sulfuric … ↩

-

Learn how bright finishing enhances aesthetics post-sandblasting.: The first of these is bright dipping, a process of bathing the extrusion in a phosphoric and nitric acid solution. The dual purpose of this is … ↩

-

Explore how brushed anodizing adds texture after sandblasting.: Anodizing aluminum aids in increasing the capabilities and properties of aluminum. Placing the aluminum in a chemical bath and washes would result in anodizing. ↩

-

Explore how anodized finishes increase durability in construction materials.: Anodised aluminium surfaces therefore offer superior scratch and abrasion resistance than coated surfaces. ↩

-

Learn about enhanced adhesion benefits for automotive applications.: Unlike other finishes, anodizing allows the aluminum to maintain its metallic appearance. Anodizing gives a deeper, richer metallic appearance than is possible … ↩

-

Explore how architecture benefits from colored anodized aluminum aesthetics.: Anodized aluminum can be colored in a full spectrum of shades. Several coloring techniques offer weather fastness suitable for architectural applications. ↩

-

Learn about automotive applications of anodized aluminum.: Anodizing offers an infinite number of gloss and color alternatives. Unlike other finishes, anodizing allows the aluminum to maintain its metallic appearance. ↩

-

Discover how consumer electronics utilize anodized aluminum.: Anodized aluminum in consumer goods provides durability and visual appeal for appliances, electronics, lighting, and hardware. Choose natural or color … ↩