How Will Aluminum Extrusion Shape the Future of Manufacturing?

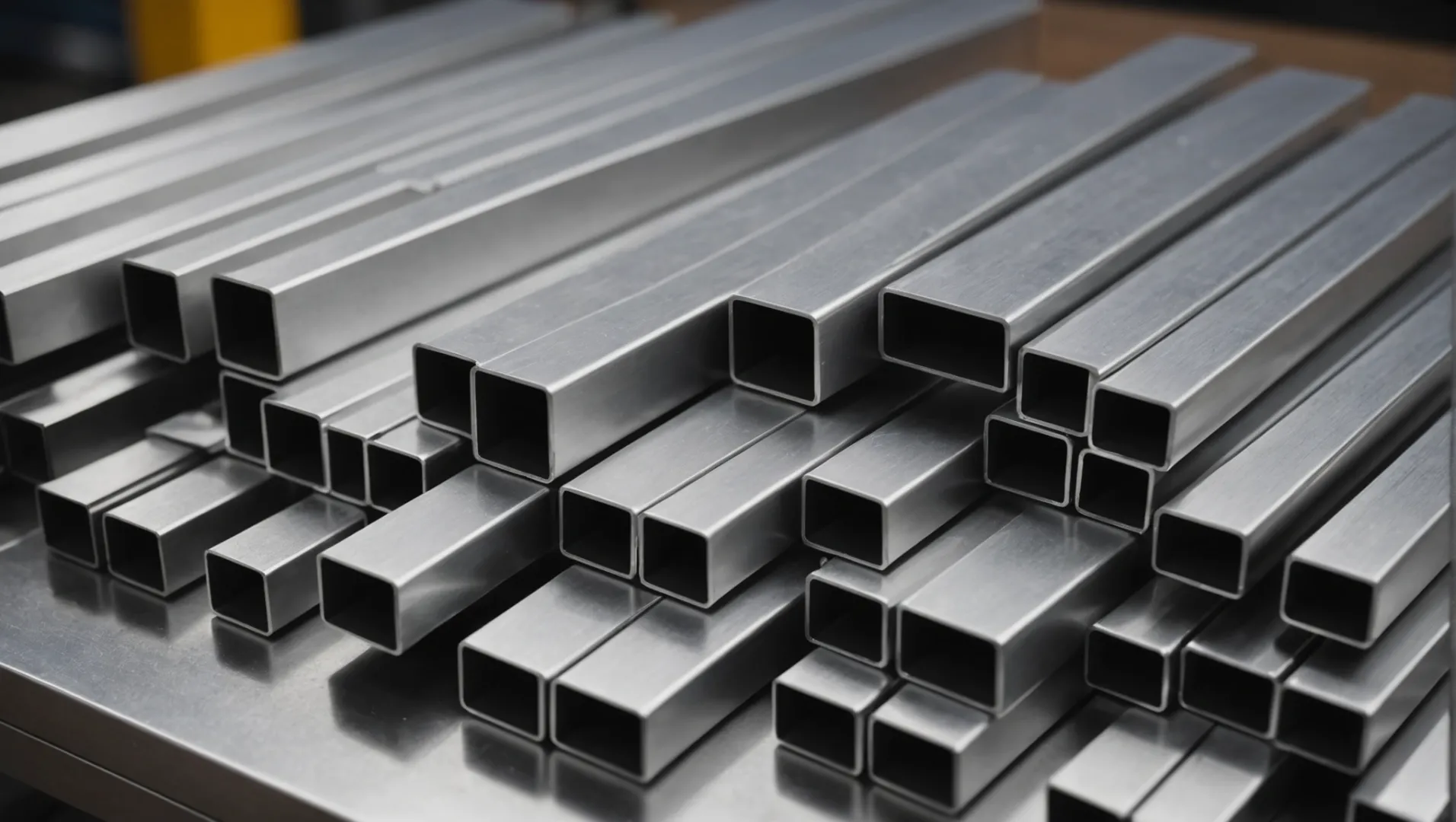

Imagine a world where manufacturing isn’t just efficient, but also incredibly sustainable and flexible. That’s what aluminum extrusion is bringing to the table!

Aluminum extrusion is set to redefine the future of manufacturing by enhancing design capabilities, improving production efficiency, and supporting sustainable practices across various industries such as construction, automotive, and renewable energy.

But how exactly does this process impact different sectors, and what innovations are on the horizon? Let’s delve into the potential applications and technological advancements that make aluminum extrusion a transformative force in manufacturing.

Aluminum extrusion improves production efficiency.True

Aluminum extrusion streamlines manufacturing, reducing material use and energy costs.

What Are the Key Advantages of Aluminum Extrusion in Manufacturing?

Aluminum extrusion is transforming manufacturing with its unique advantages and adaptability.

The key advantages of aluminum extrusion in manufacturing include cost-effectiveness, lightweight properties, high strength, versatility in design, and eco-friendliness, making it ideal for various industrial applications.

Cost-Effectiveness and Lightweight Properties

Aluminum extrusion offers a cost-effective solution due to the abundance of aluminum and the efficiency of the extrusion process. The lightweight nature1 of aluminum reduces material costs and energy consumption in transportation and handling. For instance, in the automotive industry, using extruded aluminum components leads to lighter vehicles that consume less fuel, enhancing overall efficiency.

High Strength and Durability

Despite its lightweight characteristics, aluminum exhibits excellent strength-to-weight ratios. This makes it suitable for load-bearing applications, such as construction and aerospace, where both strength and lightness are crucial. Aluminum extrusions can withstand harsh environmental conditions, resisting corrosion and maintaining their integrity over time.

Versatility in Design

Aluminum extrusion allows for intricate designs that are challenging to achieve with other materials. The ability to create complex shapes provides engineers with the flexibility to innovate across various fields. For example, architectural structures often utilize extruded aluminum to realize creative designs that blend form with function.

Eco-Friendliness and Recyclability

Aluminum is highly recyclable, which plays a significant role in reducing environmental impact. The recycling process of aluminum requires only a fraction of the energy needed to produce new aluminum from raw materials. Industries can benefit from sustainable practices2 by incorporating recycled aluminum into their products, supporting circular economy principles.

Enhancing Efficiency Across Industries

In renewable energy, extruded aluminum components are used in solar panels and wind turbines due to their lightweight and durable nature. This enhances the efficiency and lifespan of these energy solutions. Similarly, in electronics, the excellent thermal conductivity of aluminum extrusions helps in heat dissipation, maintaining optimal performance of devices.

These advantages highlight the transformative potential of aluminum extrusion in manufacturing, demonstrating its pivotal role in driving innovation and efficiency across sectors.

Aluminum extrusion is cost-effective due to material abundance.True

Aluminum's abundance and efficient extrusion process lower costs.

Extruded aluminum is unsuitable for load-bearing applications.False

Aluminum's strength-to-weight ratio makes it ideal for such uses.

How Is Aluminum Extrusion Enhancing Design Flexibility Across Industries?

Discover how aluminum extrusion is revolutionizing design flexibility, making it a go-to choice for diverse industries.

Aluminum extrusion enhances design flexibility by allowing the creation of complex profiles, reducing weight, and increasing strength, making it ideal for industries like automotive, aerospace, and architecture.

Understanding the Versatility of Aluminum Extrusion

Aluminum extrusion offers unparalleled design flexibility due to its ability to produce complex profiles with intricate geometries. This process involves forcing aluminum through a die to create specific shapes, which can be customized to meet precise requirements. The malleability of aluminum allows for designs that are not only complex but also lightweight, making it an excellent choice for industries that prioritize innovative solutions3.

Complex Profiles and Custom Designs

The ability to create complex shapes is one of the most significant advantages of aluminum extrusion. Industries such as automotive and aerospace benefit from this capability by developing components that are both lightweight and strong. For instance, automotive manufacturers can design parts that improve fuel efficiency without compromising on safety standards.

Enhanced Aesthetic and Functional Possibilities

In architecture, aluminum extrusion provides designers with the freedom to create both aesthetically pleasing and functional structures. The process supports a wide range of finishes, from anodized surfaces to powder coatings, which enhance both durability and appearance. This versatility allows architects to push the boundaries of traditional designs, introducing elements that are both visually striking4 and functionally robust.

Application Across Diverse Sectors

Beyond automotive and architecture, aluminum extrusion is pivotal in electronics for creating heat sinks and enclosures. The material’s thermal conductivity paired with custom shapes ensures optimal heat dissipation, crucial for high-performance devices. In renewable energy, aluminum’s lightweight nature enhances the efficiency of solar panels and wind turbines.

| Industry | Application Examples |

|---|---|

| Automotive | Crash management systems |

| Aerospace | Structural components |

| Architecture | Window frames, curtain walls |

| Electronics | Heat sinks |

| Renewable Energy | Solar panel frames |

By enabling the production of components tailored to specific applications, aluminum extrusion is driving innovation across various sectors, highlighting its role as a transformative force in modern manufacturing.

Aluminum extrusion reduces weight in automotive design.True

Aluminum's lightweight nature helps improve fuel efficiency in vehicles.

Aluminum extrusion is unsuitable for complex profiles.False

It excels at creating complex shapes, enhancing design flexibility.

In What Ways Does Aluminum Extrusion Contribute to Sustainability?

Aluminum extrusion is revolutionizing sustainability in manufacturing with its eco-friendly attributes and versatile applications.

Aluminum extrusion supports sustainability through material efficiency, recyclability, and energy-saving properties, significantly reducing the environmental impact in manufacturing.

Material Efficiency and Waste Reduction

One of the most significant contributions of aluminum extrusion5 to sustainability is its ability to minimize waste. By using precise extrusion techniques, manufacturers can produce components that closely match the final product dimensions, significantly reducing scrap material. This not only conserves resources but also decreases the energy needed for reprocessing waste.

Moreover, the lightweight nature of aluminum means that less material is required for manufacturing compared to other metals. This directly translates into lower raw material consumption and transport-related emissions.

Recyclability and Resource Conservation

Aluminum is one of the most recyclable materials available. Extruded aluminum products can be melted down and reused repeatedly without losing quality or integrity. The recycling process requires only 5% of the energy needed to produce new aluminum from bauxite ore, making it a cornerstone of sustainable practices.

Manufacturers are increasingly utilizing recycled aluminum, further enhancing the sustainability of their operations. This shift not only conserves natural resources but also reduces landfill waste.

Energy Efficiency in Applications

Aluminum’s lightweight properties contribute to energy savings in its applications. For example, automotive industries6 use aluminum extrusion for vehicle parts to improve fuel efficiency by reducing overall vehicle weight. Similarly, aluminum’s thermal conductivity makes it an excellent choice for applications like heat exchangers and solar panels, where efficient energy transfer is essential.

Environmental Impact and Lifecycle Assessment

Conducting a lifecycle assessment of aluminum extruded products reveals their long-term environmental benefits. Though energy-intensive during initial production, the subsequent energy savings and recyclability of aluminum compensate for this initial footprint. The ongoing development of cleaner production technologies also mitigates the environmental impact.

By integrating aluminum extrusion7 into sustainable manufacturing strategies, industries can significantly enhance their environmental responsibility, leading to a greener future.

Aluminum extrusion reduces manufacturing waste.True

Precise extrusion techniques minimize scrap material, conserving resources.

Recycling aluminum requires more energy than producing new.False

Recycling aluminum uses only 5% of the energy needed for new production.

What Innovations in Aluminum Extrusion Are Driving Future Manufacturing Trends?

Aluminum extrusion is evolving with new technologies, transforming how industries approach manufacturing.

Innovations like 3D printing integration, smart manufacturing, and new alloy developments are driving aluminum extrusion’s role in future manufacturing trends.

3D Printing Integration in Aluminum Extrusion

One of the most significant innovations in aluminum extrusion is the integration of 3D printing8. This hybrid approach allows manufacturers to create complex designs that were previously difficult or impossible with traditional methods. By combining extrusion with additive manufacturing, companies can produce lightweight yet durable components tailored to specific industrial needs, such as aerospace and automotive applications. This synergy not only accelerates production but also reduces material waste, aligning with sustainability goals.

Smart Manufacturing and Automation

The adoption of smart manufacturing technologies is revolutionizing aluminum extrusion. Through the use of IoT devices and AI-driven analytics, manufacturers can monitor the extrusion process in real-time, enhancing precision and efficiency. Automated systems enable continuous production with minimal human intervention, reducing error rates and downtime. This technological leap is crucial for meeting the increasing demand for high-performance materials in sectors like construction and renewable energy.

Development of Advanced Alloys

Recent advancements in alloy technology have broadened the applications of aluminum extrusion. New alloys offer superior strength-to-weight ratios and enhanced resistance to environmental factors such as corrosion. These properties make them ideal for use in challenging environments, from deep-sea exploration equipment to high-altitude drones. Moreover, the ability to tailor alloy compositions opens up opportunities for bespoke solutions across various industries.

Sustainability and Recycling Enhancements

The drive towards sustainability has spurred innovations in recycling methods within aluminum extrusion. Modern techniques allow for the efficient recovery and reuse of aluminum scrap, significantly reducing the carbon footprint associated with manufacturing processes. This not only supports environmental objectives but also cuts costs and conserves resources. As global regulations tighten on emissions and waste, such innovations are pivotal for maintaining competitive advantage.

By exploring these technological advancements, manufacturers can position themselves at the forefront of the industry’s evolution, tapping into new markets and enhancing their product offerings.

3D printing allows complex aluminum designs.True

3D printing integration enables creating intricate designs previously unfeasible.

Smart manufacturing increases aluminum extrusion errors.False

Smart manufacturing reduces errors by enhancing precision and efficiency.

Conclusion

In a nutshell, aluminum extrusion is poised to redefine manufacturing by fostering innovation and efficiency. As technology evolves, embracing these changes can lead to more sustainable and versatile production methods.

-

Understand how aluminum’s density contributes to its lightweight nature.: Aluminum has a low density of 2.7 g/cm³ and is thus a lightweight metal. It is three times lighter than steel yet has much higher strength-to- … ↩

-

Discover the eco-friendly benefits of recycling aluminum materials.: The environmental benefits of using recycled aluminum are extensive—including reducing energy use, mining pollution, shipping pollution and … ↩

-

Explore how industries use aluminum extrusion for groundbreaking designs.: Over the years, technological advancements have significantly improved this process, resulting in higher precision, better quality, and more complex shapes. ↩

-

See stunning architectural designs enabled by aluminum extrusion.: Aluminum is a highly effective and affordable option for architectural applications. It is lightweight, malleable, and environmentally friendly. ↩

-

Learn about precise extrusion techniques reducing waste material.: Used air filters, used plastic sheeting, and ash which results from the removal of paint from conveyor hooks in the burn-off oven are combined and hauled away … ↩

-

Discover how aluminum improves fuel efficiency in vehicles.: Extrusions are used for the front and rear frame rails, side rails. … Most extrusions are hidden away from the vehicle owner’s touch and sight. Not these parts. ↩

-

Explore the long-term environmental benefits of aluminum products.: In this study, the LCA model for secondary extruded aluminum represents a cradle- to-gate procedure, beginning at recycling aluminum scrap and ending in the … ↩

-

Discover how 3D printing enhances aluminum extrusion capabilities.: I understand aluminium extriusion is cheap and stiff compared to price since it is extrusion, we need to print for aligning parts, why not just use milled … ↩