Start Form 200KG

Quote & Estimation

Begin with a thorough evaluation of the design's feasibility, followed by a prompt, detailed estimate.

Home > Polished Aluminum Angle Manufacturer

Fully customizable polished aluminum angles designed to meet your specific requirements for size, alloy, finish and processing.

Large-Scale Manufacturing:Our factory spans 1,000 mu (about 667,000 m²), with full in-house capabilities from aluminum smelting and billet casting to extrusion, surface treatment, and CNC machining.

One-Stop Solution:With 43 extrusion lines (500–5500 tons) and a dedicated mold partner, we provide fast production, custom profiles, and integrated services to simplify your supply chain.

Quality You Can Trust:Strict quality control ensures consistent dimensions, strength, and finish, reducing your risk and increasing reliability.

Fast Delivery & Cost Efficiency:Self-produced billets, in-house processing, and batch production mean faster lead times and lower overall costs.

Advanced Finishing Options:Anodizing and both vertical and horizontal powder coating lines deliver durable, high-quality surface finishes tailored to your product needs.

STEPS

Begin with a thorough evaluation of the design's feasibility, followed by a prompt, detailed estimate.

Creating a prototype to assess dimensions and ensure the mold's precision aligns with the requirements.

Producing the aluminum profile with pinpoint accuracy to the given specifications and applying desired finishes.

Tailored packaging for the extruded profiles, ensuring safe and efficient loading for prompt delivery.

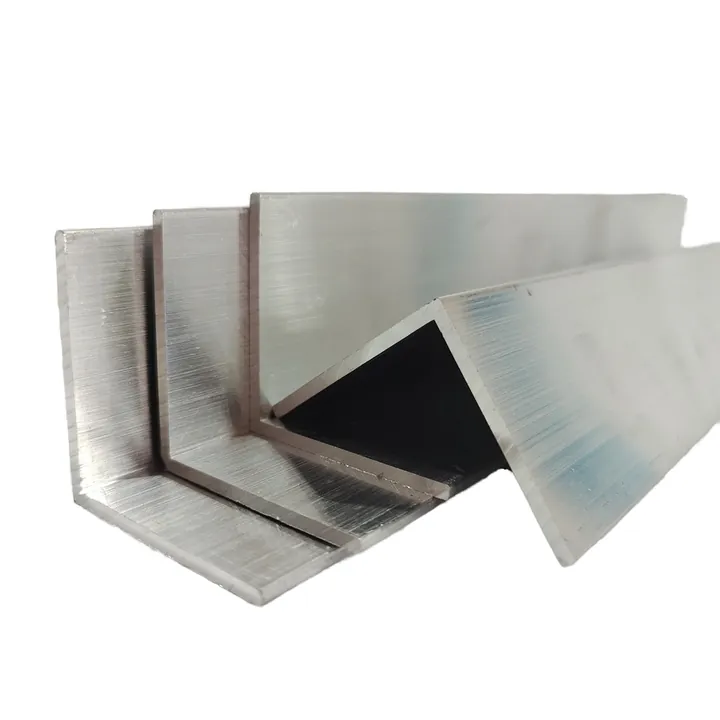

Polished Aluminum Angles feature a precision-engineered, mirror-like surface that elevates both functionality and aesthetics. The product is manufactured from durable 6000-series alloys such as 6061 and 6063, in T5 or T6 tempers, providing reliable strength, corrosion resistance and formability.

Ideal for protective edging, architectural frameworks and decorative trim, these polished angles deliver both visual appeal and structural performance. The polished finish makes them well suited for applications requiring attention to detail and cleanliness.

Multiple surface treatment options-polished, brushed, anodized, or powder coated-offer flexibility to match design themes or environmental demands. Treatments are applied with precision to maintain both finish quality and corrosion protection.

Comprehensive customization includes leg dimensions, thickness, alloy selection and secondary processing such as CNC cutting, bending, welding and drilling. Packaging choices are tailored to preserve surface integrity during transit and installation.

With strong manufacturing standards and flexible service capabilities, these polished aluminum angles support seamless integration into your architectural or industrial projects. Their consistent quality and refined presentation inspire confidence in both form and function.

Start Form 200KG