How to Choose Aluminum LED Strip Extrusion Channel?

If you pick the wrong LED channel, your lighting may overheat, look uneven, or be hard to install.

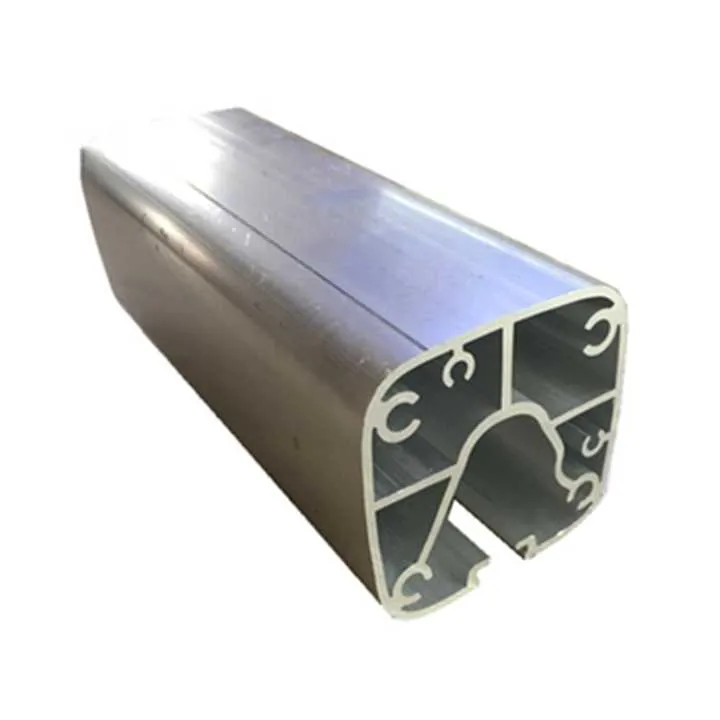

The right aluminum LED extrusion depends on heat control, strip size, light diffusion, and installation needs.

I will walk you through the key points that make channel selection easier and more cost-effective.

What channel profiles support LED heat dissipation?

If you choose a channel only for looks, your LED strips may overheat and fail early.

Wide and thick aluminum channels with proper surface contact improve heat dissipation for LED strips.

Understanding heat control in LED channels

When I supplied LED profiles for a large hotel renovation, the client initially chose slim decorative channels. After six months, heat damage caused dimming and color shift. We replaced them with deeper, heavier channels that acted like heat sinks. The performance difference was clear.

Heat dissipation depends on:

- Base width and thickness – More aluminum means better heat spread.

- Surface contact with LED PCB – Full flat contact transfers heat faster.

- Mounting material – Metal surfaces conduct heat away; wood traps it.

- Ventilation design – Openings or non-sealed mounting can help airflow.

Here’s a quick reference table:

| Channel Feature | Effect on Heat Dissipation | Recommendation |

|---|---|---|

| Wide aluminum base | Higher heat capacity | Use ≥ 15mm base width |

| Thick walls | Slower heat buildup | ≥ 1.2mm wall thickness |

| Direct PCB contact | Better thermal transfer | Avoid raised ridges |

| Enclosed mounting | Poor heat release | Add ventilation slots |

A thicker and wider channel may cost more but prevents LED overheating, which saves money in replacements.

The thickness of aluminum walls has no effect on LED heat dissipationFalse

Thicker aluminum walls store and spread heat more effectively, preventing overheating.

Good surface contact between LED PCB and channel base improves heat dissipationTrue

Direct contact allows heat to transfer quickly from LED to aluminum for cooling.

How to choose size based on strip width and mounting?

If you pick the wrong channel size, your LED strip may not fit, or you may see unwanted light spots.

Match the internal width and height of the channel to your LED strip’s PCB width and mounting needs.

Matching channel dimensions to LED strip size

In one residential project, the client bought narrow 10mm channels for 12mm-wide LED strips. We had to trim the strips, which damaged some solder pads. Since then, I always double-check PCB width before ordering.

Important sizing steps:

- Measure LED PCB width – Common widths are 8mm, 10mm, 12mm.

- Add clearance for wires – Especially if strips have side leads.

- Consider diffuser height – Taller covers help blend light points.

- Check mounting space – Some installations require ultra-slim profiles.

Example matching table:

| LED Strip Width | Recommended Channel Inner Width | Mounting Type |

|---|---|---|

| 8mm | 10–12mm | Cabinet, display case |

| 10mm | 12–14mm | Ceiling cove, shelf edge |

| 12mm | 14–16mm | Outdoor or high-brightness |

Remember, channel depth affects light diffusion. Deeper channels reduce spotting but take more space.

LED channel width should always be equal to the LED PCB width for a snug fitFalse

A small clearance is needed to prevent bending or damaging the LED strip during installation.

Taller LED channel covers can reduce visible LED hotspotsTrue

Increasing the distance between LEDs and the cover helps blend light into a uniform line.

Which finishes enhance light diffusion or aesthetics?

If you choose the wrong finish, your lighting may cause glare or look unprofessional.

Matte, opal, or frosted covers diffuse light better, while clear covers keep maximum brightness.

Choosing finishes for both function and style

During a retail store fit-out, the designer wanted bright display lighting without visible LED dots. We used opal diffusers, which softened the light and created a premium look. Although they reduced brightness slightly, the visual quality improved.

Common diffuser options:

- Clear – Maximum output, visible LED points.

- Frosted – Softens edges, slight brightness loss.

- Opal/Matte – Best diffusion, 15–30% brightness reduction.

Channel body finishes:

- Anodized silver – Neutral look, scratch resistant.

- Black anodized – Sleek for dark interiors, hides edges.

- Powder coated white – Matches white ceilings and walls.

Here’s a comparison table:

| Finish Type | Light Diffusion | Brightness Loss | Typical Use Case |

|---|---|---|---|

| Clear | Low | 0–5% | Task lighting, displays |

| Frosted | Medium | 10–15% | Decorative, work areas |

| Opal/Matte | High | 15–30% | Retail, hospitality |

Aesthetic finishes also help the profile blend with surroundings or stand out as a design element.

Opal diffusers allow the most light to pass through without any lossFalse

Opal diffusers provide the highest diffusion but reduce brightness by up to 30%.

Black anodized aluminum channels can visually blend into dark environmentsTrue

Black anodized finishes reduce visual contrast, making profiles less noticeable in dark spaces.

How to ensure ease of installation and accessory compatibility?

A poorly chosen channel can turn installation into a frustrating, time-consuming task.

Select channels that come with matching end caps, mounting clips, and compatible connectors.

Making installation faster and cleaner

I remember a contractor who bought cheap channels without accessories. He had to custom-make mounting brackets, which delayed the project by a week. Accessories make installation faster, neater, and safer.

Look for:

- Pre-drilled mounting clips – Save drilling time.

- End caps with wire holes – Keep wiring tidy.

- Diffuser snap-fit design – Easy removal for maintenance.

- Corner connectors – Allow seamless angle changes.

- Surface or recessed mount options – Fit different project types.

Installation tip:

Always plan wire routing before fixing channels. This avoids having to remove and re-mount profiles.

Here’s a quick checklist:

| Accessory | Purpose |

|---|---|

| End caps | Protects ends, hides wiring |

| Mounting clips | Fast, secure attachment |

| Corner connectors | Smooth joins at angles |

| Diffuser covers | Light control and protection |

Having a complete kit avoids mismatched parts and ensures the system looks professional.

LED channels with snap-fit diffusers are easier to maintain and cleanTrue

Snap-fit covers allow quick removal for cleaning or LED replacement without tools.

End caps are optional and have no functional benefitFalse

End caps protect the LED strip ends from dust and damage while improving the finish.

Conclusion

Choosing the right aluminum LED strip extrusion channel is about more than looks. You need to consider heat dissipation, strip size fit, diffuser type, and installation accessories. When these factors align, your lighting will last longer, look better, and install faster.