What does ‘mill finish’ of aluminum mean?

Aluminum comes in many surface types—but few are as misunderstood as “mill finish.” It sounds technical, yet many engineers and buyers don’t fully understand what it means or when to use it.

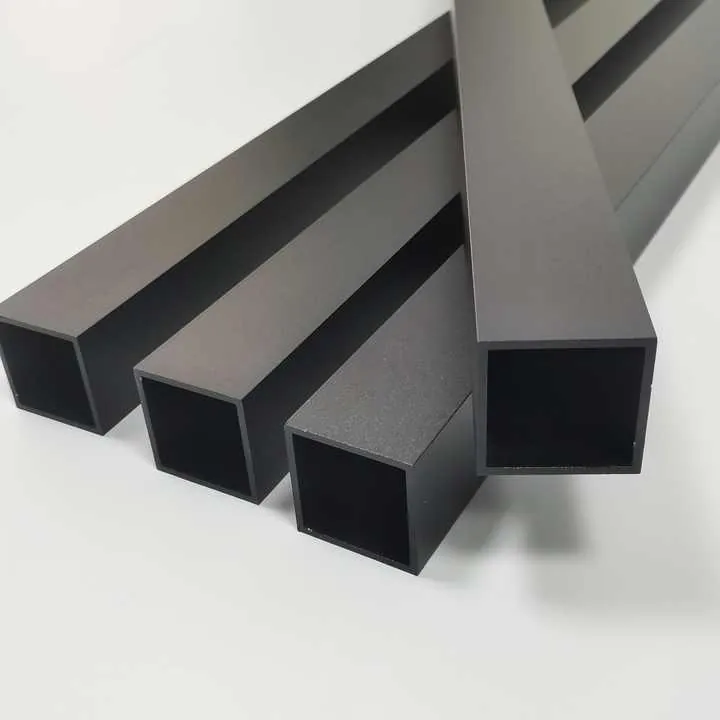

Mill finish aluminum means aluminum that comes directly out of the extrusion or rolling mill without any post-processing. It has a raw, unfinished surface.

Most people assume aluminum always needs a coating or anodizing. But that’s not always true. In some cases, mill finish is the most cost-effective and practical choice—if you understand its strengths and weaknesses.

What is the basic definition of mill finish aluminum?

When aluminum exits the production line—either after extrusion, casting, or rolling—it has a natural surface. This is called "mill finish." It hasn’t been polished, anodized, powder-coated, or chemically treated.

Mill finish aluminum refers to aluminum in its natural state after it is extruded or rolled, with no additional surface treatment or protection.

Characteristics of Mill Finish

Here are the typical traits of mill finish aluminum:

| Property | Description |

|---|---|

| Surface appearance | Dull, metallic grey or silvery |

| Texture | Slightly rough, can show tooling |

| Oxidation | Will develop a thin oxide film |

| Protection | None; bare aluminum |

| Surface uniformity | May have streaks, marks, or patches |

Mill finish isn’t meant to be pretty. It’s functional, fast to produce, and cost-efficient. It’s often used as an intermediate product that will be coated, welded, or formed later. But in some cases, especially in internal structures or low-visibility parts, mill finish is the final form.

Mill finish aluminum has no added surface treatments.True

It refers to aluminum that comes directly from the mill without coatings or polishing.

Mill finish aluminum has a shiny and reflective surface.False

Its surface is usually dull or matte, not polished or reflective.

How does mill finish compare to anodized or coated aluminum?

Anodized and coated aluminum go through extra processing steps that give them specific surface properties. Mill finish skips all that. So the differences are easy to see—in looks, performance, and price.

Compared to anodized or coated aluminum, mill finish has no corrosion resistance, lower aesthetic appeal, and more surface variability, but it’s cheaper and faster to produce.

Surface Treatment Comparison

| Property | Mill Finish | Anodized | Powder Coated |

|---|---|---|---|

| Appearance | Dull or patchy | Uniform and colored | Custom colors, smooth |

| Corrosion Resistance | Low | High | High |

| Cost | Lowest | Moderate | Higher |

| UV Resistance | Poor | Excellent | Depends on paint quality |

| Surface Hardness | Soft | Medium to hard | Medium to hard |

| Electrical Conductivity | High | Low | Very low |

For example, I often supply mill finish aluminum to clients who plan to do their own powder coating. They don’t want to pay extra for a finish they’ll just strip off. But a furniture client needed a glossy white finish with outdoor protection—so they chose powder-coated aluminum.

Anodized aluminum has better corrosion resistance than mill finish aluminum.True

Anodizing creates a protective oxide layer that resists corrosion and wear.

Mill finish aluminum always looks more polished than coated aluminum.False

Mill finish is raw and unpolished, often with visible marks or streaks.

What are the advantages and limitations of mill finish?

Mill finish aluminum is simple and direct. It offers clear benefits—especially for industrial use. But it also comes with limitations that need to be considered before use.

The biggest advantages of mill finish are low cost, immediate availability, and high conductivity. But it offers poor corrosion resistance and is not visually consistent.

Pros and Cons

| Advantages | Limitations |

|---|---|

| Cheapest aluminum finish available | No corrosion protection |

| Fast delivery—no processing delay | Scratches and oxidation develop easily |

| Great for welding and fabrication | Non-uniform surface appearance |

| High electrical conductivity | Not suitable for decorative use |

When Mill Finish Makes Sense

- Internal structural parts – where the aluminum is not exposed.

- Electrical grounding parts – conductivity is high.

- Pre-treatment stages – when the customer will anodize or paint later.

When You Should Avoid It

- Outdoor exposure – corrosion happens quickly.

- Aesthetic uses – appearance is rough and patchy.

- Wear-heavy applications – surface scratches easily.

I had a German customer building machinery frames. They only needed internal components that would never be seen or exposed. Mill finish was perfect—cheaper, faster, and good enough. But another client made kitchen fixtures; they needed brushed or anodized finishes for looks and hygiene.

Mill finish aluminum is often used for internal or hidden components.True

It’s cheap and functional when the part won't be seen or weathered.

Mill finish is ideal for high-traffic decorative surfaces.False

It scratches easily and has poor appearance uniformity.

Can mill finish aluminum be treated for outdoor durability?

Mill finish aluminum is not designed for outdoor use. But that doesn’t mean it can’t be used outdoors—if you treat it first. There are several ways to improve its durability.

Yes, mill finish aluminum can be treated with coatings, anodizing, or sealants to make it suitable for outdoor use. But untreated, it will corrode quickly when exposed to moisture or salt.

How to Treat Mill Finish for Outdoor Use

- Anodizing – Adds a protective oxide layer. Improves corrosion resistance.

- Powder Coating – Adds color and protection. UV and moisture resistant.

- Clear Coatings – Clear lacquers or sealants slow down oxidation.

- Painting – Simple and effective for light-duty applications.

- Chemical Conversion Coating – Used as a base for paint or bonding.

What Happens If You Don’t Treat It?

| Environment | Expected Outcome (Untreated Mill Finish) |

|---|---|

| Indoor dry use | Will develop light oxide, no rust |

| Humid environment | Oxidation spots, pitting over time |

| Outdoor (rain, sun) | Corrosion starts in weeks or months |

| Coastal or salty air | Rapid white corrosion, structural damage |

I once supplied mill finish tubing for a solar frame project. The installer didn’t coat it—and within six months, white spots and pitting appeared. They had to strip and recoat everything. After that, they always started with powder-coated or anodized aluminum.

Mill finish aluminum must be treated before outdoor use.True

Without protection, it corrodes quickly in moisture or UV-rich environments.

Untreated mill finish can last outdoors for years without issues.False

It’s prone to oxidation and corrosion unless properly treated.

Conclusion

Mill finish aluminum is simple, affordable, and useful for many applications—especially indoors or behind the scenes. But if looks or protection matter, it’s best to treat or upgrade the surface.