What Are Use for Industrial Aluminium Profile – 9 Types?

I used to think aluminum profiles were just for windows and doors. But after working on some factory projects, I found out how widely they’re used. They’re everywhere in industry.

Industrial aluminum profiles are used to build everything from machine frames to workstations, safety guards, and even testing rooms. They are strong, flexible, and easy to assemble.

I want to share how these profiles are used in different industries. I’ll also show how each use case helps cut costs, improve safety, and make systems easier to manage.

What industries commonly use industrial aluminum profiles?

I always see aluminum profiles in factories. But then I noticed them in other places too. Warehouses, labs, and even clean rooms all use them. That made me curious.

Industries like automation, electronics, medical, logistics, and automotive all use industrial aluminum profiles to build custom structures and systems.

When I visited a robot assembly plant, I saw aluminum frames holding sensors, conveyor belts, and robotic arms. The maintenance team said they preferred aluminum because it’s light, doesn’t rust, and is easy to reconfigure.

In a logistics warehouse, aluminum frames supported roller conveyors and storage systems. The staff liked that they could adjust the frames without welding. They just needed an Allen key.

In electronics factories, profiles are used for ESD-safe workstations and equipment stands. These industries need clean, modular systems, and aluminum fits well.

Hospitals and labs also use profiles for movable tables, trolleys, and cleanroom partitions. The smooth anodized surface is easy to clean, which helps maintain hygiene.

Automotive testing centers use large aluminum frames to mount car parts and sensors. In these cases, high-precision alignment and vibration resistance are important, and aluminum delivers that.

Here’s a simple table of key industries and their use cases:

| Industry | Common Uses with Aluminum Profiles |

|---|---|

| Automation | Machine frames, sensor mounts, conveyors |

| Logistics | Racks, flow racks, roller systems |

| Electronics | ESD workstations, enclosures |

| Healthcare | Cleanroom tables, carts, medical device stands |

| Automotive | Testing rigs, part frames, robot arms |

Electronics, logistics, and automation all use industrial aluminum profiles.True

These industries benefit from the modular and clean properties of aluminum systems.

Industrial aluminum profiles are only used in building construction.False

They are widely used in machinery, testing, storage, and cleanroom applications.

How are industrial aluminium profiles used to build workbenches & racks?

I remember building my first workbench with aluminum profiles. I didn’t need welding or painting. I just cut the profiles and used connectors. It was done in a few hours.

Industrial aluminum profiles are used to build adjustable, modular workbenches and racks for factories, warehouses, and labs. They can be custom-built and reconfigured quickly.

Workbenches made from T-slot profiles are common on production lines. Workers adjust the height or add accessories like tool holders or lights. Since the structure is modular, changes are easy and low-cost.

Racks and shelves built with aluminum can hold bins, cartons, or tools. I’ve used them to create FIFO (first-in, first-out) flow racks. You just need to add angled rollers.

These systems improve workflow and space use. You can customize shelf levels or width based on your need. You don’t need welding or heavy tools—just a hex wrench.

Benefits of aluminum workbenches and racks

- Modular: Easy to reconfigure as processes change

- Strong: Hold weight without bending or warping

- Clean: No paint peeling, smooth finish for clean rooms

- Cost-effective: Cheaper than welded steel in many cases

Here’s a comparison table:

| Feature | Aluminum Profile System | Welded Steel System |

|---|---|---|

| Assembly Time | Quick, no welding | Slow, needs welding |

| Adjustability | High | Low |

| Cleanroom Compatible | Yes | Not always |

| Tooling Required | Hex wrench | Welding and cutting |

Aluminum profiles make it easy to build and modify factory workbenches without welding.True

T-slot connections allow for fast and flexible design changes.

Once aluminum racks are built, they cannot be reconfigured.False

Aluminum racks are modular and easy to adjust anytime.

Why are T-slot aluminum profiles favoured for machine frames?

When I helped build a packaging line, we used T-slot frames. I asked why not use welded steel. The engineer said T-slot frames are faster to set up and easier to repair.

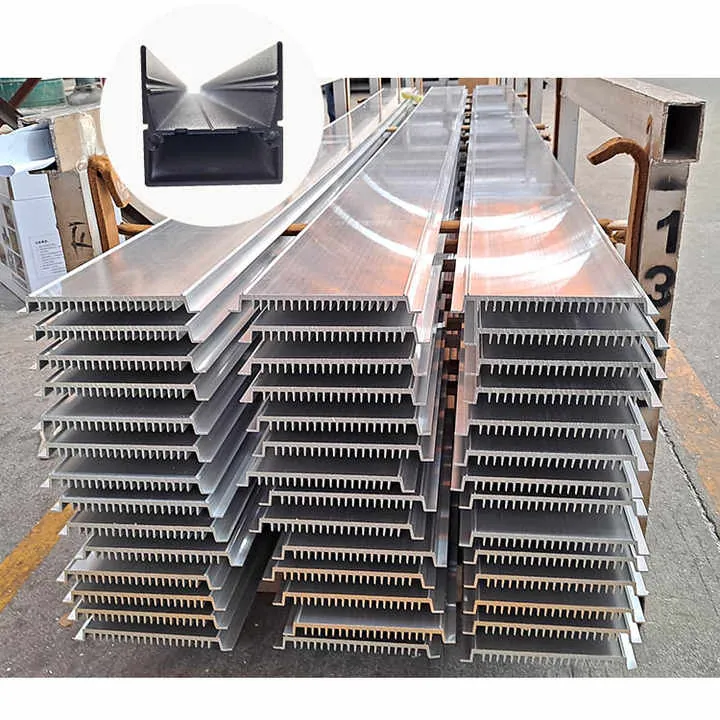

T-slot aluminum profiles are preferred for machine frames because they offer fast assembly, modularity, and easy access for wiring and components.

The T-slots allow you to attach parts at any point. You can mount panels, control boxes, sensors, or even wheels without drilling. You slide T-nuts into the slot and tighten the bolt. That’s it.

For machine builders, time matters. They can assemble the frame in less than half the time needed for welding steel. Also, if a design changes, they don’t have to scrap the old frame—just move the parts.

I’ve seen engineers add guards, doors, or feet to machines without disassembly. They use brackets that slide right into the T-slot.

Key reasons to use T-slot profiles for machines:

- Quick setup

- Tool-free adjustments

- Reusable materials

- Good cable management

- Light but strong enough

For large frames, I learned to use 45×45?mm or even 90×90?mm profiles. Smaller machines work well with 30×30?mm.

T-slot aluminum profiles allow easy mounting and adjustment without drilling.True

You can insert fasteners anywhere along the slot.

Machine frames with aluminum T-slot profiles must be welded for stability.False

These frames are assembled with brackets and fasteners, not welding.

What safety structures can be made with industrial aluminium profiles?

Safety is always a concern on the shop floor. I once built a guard to separate a press machine from the walking path. I used 40×40?mm profiles and yellow panels.

Industrial aluminum profiles are used to build guards, fencing, enclosures, and partitions that protect workers from hazards. They are light, modular, and safe to install.

Common safety structures include:

- Machine guarding: Transparent polycarbonate panels in an aluminum frame protect operators

- Safety fencing: Perimeter guards around robots or conveyors

- Partitions: Separate noisy or dangerous areas

- Door frames: For access panels or sliding gates

One big plus is visibility. I like using clear panels with aluminum. You can see the machine but stay protected. Also, you can add locks, hinges, or switches easily to the frame.

Most factories use 30×30?mm or 40×40?mm profiles for these tasks. If extra strength is needed, 45×45?mm works best.

Aluminum also helps meet OSHA or CE safety rules. The modular system means if one section breaks, you can replace just that part.

Aluminum profiles can be used to build machine guards and safety fences.True

They provide modular, strong, and customizable protection systems.

Safety structures using aluminum profiles cannot be combined with plastic panels.False

You can mount polycarbonate or mesh panels easily into the slots.

How are aluminium profiles used in automotive testing and clean rooms?

When I toured a car testing lab, I noticed that most of the structures were aluminum. Even test frames for engines and parts. Then in a cleanroom factory, I saw tables, trolleys, and enclosures all built with aluminum.

Aluminum profiles are used in clean rooms and test labs because they are non-corrosive, smooth, and easy to clean. They support high-precision testing structures.

In auto test centers, engineers build test rigs using 45×45?mm or 90×90?mm profiles. These hold heavy parts like engines, gearboxes, or suspensions. The structure must stay aligned for precise readings.

The T-slots allow sensors and clamps to be positioned accurately. I’ve seen laser alignment tools mounted directly onto the profile.

In cleanrooms, where even dust can ruin electronics, profiles are ideal. The anodized surface is smooth and non-reactive. You can wipe it clean easily.

Common cleanroom applications:

- ESD-safe workstations

- Airflow covers

- Monitor arms

- Filter housing frames

You can also ground aluminum frames to control static. That’s important for sensitive devices.

Aluminum profiles are suitable for cleanrooms because they are easy to clean and don’t rust.True

Their smooth, anodized finish resists corrosion and collects less dust.

Aluminum frames cannot support heavy loads during automotive testing.False

Large profiles like 90×90?mm can support engines or heavy tools.

Conclusion

Industrial aluminum profiles are used in many industries for many purposes. I’ve built workbenches, safety guards, machine frames, and cleanroom structures with them. They’re strong, clean, and flexible. The T-slot system makes assembly simple. From logistics to labs, profiles solve real problems. That’s why they’re everywhere.